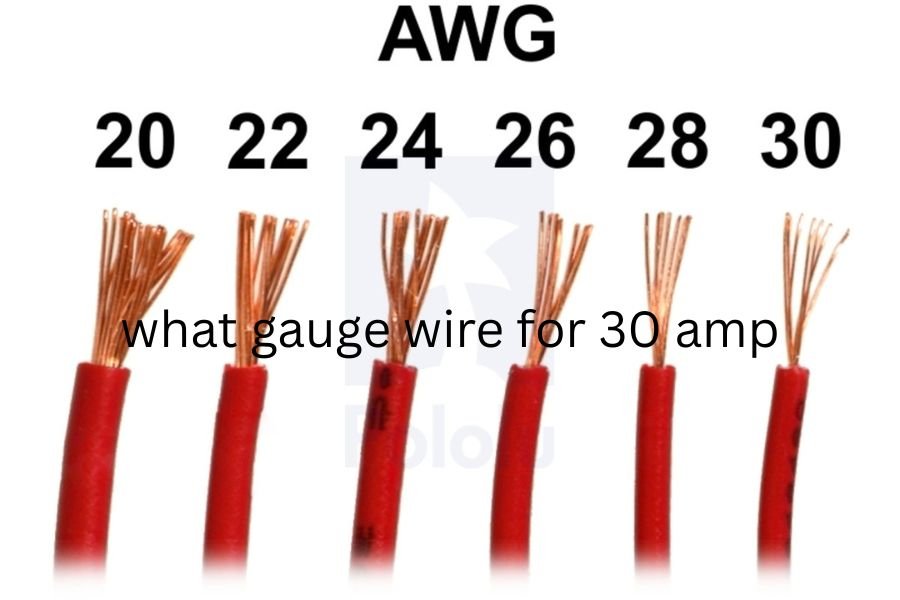

When you hear the term “what gauge wire for 30 amp,” it refers to the thickness or diameter of the electrical wire that can safely carry 30 amps of current. Wire gauge is measured using the American Wire Gauge (AWG) system, where a smaller number indicates a thicker wire. Choosing the right wire gauge is essential because it affects how safely electricity can flow through the circuit. If the wire is too thin, it can overheat, leading to electrical hazards. Therefore, selecting the correct wire size ensures efficiency and safety.

For a 30-amp circuit, the correct wire size is 10 AWG copper, which safely carries the required load without overheating. If the wire run is longer than about 100 feet, upgrading to 8 AWG helps reduce voltage drop. Always follow NEC guidelines to ensure safe and code-compliant installation.

In this article, we discuss the topic of “what gauge wire for 30 amp”.

Why Wire Size Matters For a 30 Amp Circuit

Wire size plays a crucial role in maintaining the safety and efficiency of electrical circuits. For a 30 amp circuit, using the correct gauge prevents overheating and reduces the risk of electrical fires. Undersized wires cannot handle the current load and may cause insulation damage. On the other hand, an appropriately sized wire ensures that your appliances and systems operate efficiently. Always match your wire size with your circuit’s amperage to maintain compliance with electrical codes.

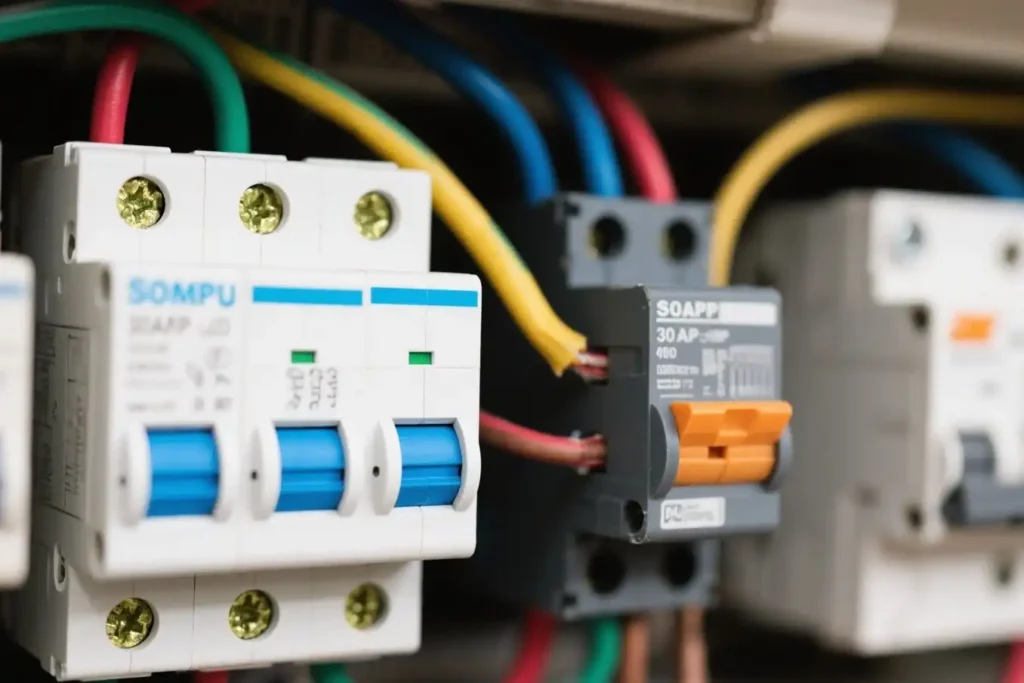

The Role of a Circuit Breaker in Electrical Safety

A circuit breaker acts as a safety device that protects your home’s wiring system from overloads. In a 30 amp setup, the breaker will automatically shut off the current if it exceeds the rated load. This helps prevent damage to electrical devices and reduces the risk of fire. The circuit breaker also ensures that your wiring does not carry more current than it can safely handle. It is a critical component in all electrical installations and must match the wire gauge used.

What Is a 30 Amp Breaker Used For?

A 30 amp breaker is typically used for circuits that power heavy-duty appliances or equipment. Common examples include electric dryers, air conditioners, water heaters, and RV power outlets. These devices require more power than standard outlets can provide. Installing a 30 amp circuit with the proper wire gauge ensures that your equipment receives stable power without risking overload. Understanding what a 30 amp breaker powers helps in selecting the right wire size and breaker combination.

Basics of Wire Gauge and Amperage

Wire gauge and amperage are directly related to each other. The thicker the wire, the higher the current it can carry safely. For example, 10-gauge wire is typically suitable for 30 amps, while smaller gauges like 12 or 14 are meant for lower currents. The AWG system defines this relationship, making it easier for electricians to choose appropriate wiring. Using the right combination of wire size and amperage prevents overheating, voltage drops, and equipment damage.

The American Wire Gauge (AWG) System Explained

The AWG system is a standardized way of measuring the diameter of electrical conductors. It assigns numbers to specific wire sizes, where a lower number means a thicker wire. For instance, 10 AWG wire is thicker than 12 AWG. The AWG chart helps electricians determine the safe current-carrying capacity of a wire. For a 30 amp circuit, 10 AWG is the commonly recommended size. This standard ensures consistent and safe wiring across all electrical applications.

Recommended Wire Gauge for 30 Amp Circuits

According to electrical code standards, the recommended wire gauge for a 30 amp circuit is 10 AWG copper wire. This size provides sufficient thickness to handle the current safely without excessive heat buildup. For longer wire runs or aluminum wiring, a larger gauge like 8 AWG might be needed. Always check local electrical codes and manufacturer guidelines before installation. Using the correct wire gauge ensures the reliability and longevity of your electrical system.

Is 10 Gauge Wire Suitable for 30 Amps?

Yes, 10 gauge wire is suitable for 30 amps in most residential and commercial applications. It can safely handle the load without overheating under standard conditions. However, factors like distance, temperature, and insulation type can affect performance. If the wire run is particularly long, you may need to use an 8 gauge wire to compensate for voltage drop. Always ensure the wire type and length are appropriate for the specific application to maintain safety.

Can You Use 12 Gauge Wire for 30 Amps?

No, using 12 gauge wire for a 30 amp circuit is unsafe and violates electrical codes. Twelve-gauge wire is rated for up to 20 amps, and using it on a higher current can cause overheating and fire hazards. The insulation around the wire may melt, leading to short circuits or equipment damage. Always match your wire size to your circuit’s amperage rating to ensure compliance and protect your property from electrical risks.

When to Use 8 Gauge Wire for a 30 Amp Breaker

An 8 gauge wire may be required for a 30 amp breaker when the wire run exceeds typical distance limits. Long wire runs can lead to voltage drop, meaning the electrical device at the end may receive less power. To counter this, a thicker wire with a lower gauge number is used. If your 30 amp circuit extends over 100 feet, using 8 AWG instead of 10 AWG is a good safety measure. It maintains power efficiency and prevents overheating.

Copper vs. Aluminum Wire for 30 Amp Circuits

When wiring a 30 amp circuit, choosing between copper and aluminum wire is crucial. Copper wire is more conductive, durable, and resistant to heat, making it the preferred choice for most electricians. Aluminum wire, while cheaper and lighter, has a lower conductivity and can expand or contract with temperature changes. This may loosen connections over time, creating safety concerns. If you must use aluminum wire, choose a larger gauge like 8 AWG instead of 10 AWG copper. Always use approved connectors and anti-oxidant paste for aluminum wiring.

Understanding Wire Ampacity Ratings

Ampacity refers to the maximum current a wire can carry safely without overheating. Each wire gauge has a specific ampacity rating determined by its material, insulation type, and installation conditions. For example, a 10 AWG copper wire generally supports 30 amps, while aluminum may handle slightly less. Exceeding ampacity can cause wire insulation to break down, leading to dangerous situations. Always check ampacity charts before selecting a wire to ensure your system remains within safe limits.

Wire Size Ampacity Chart for Reference

A wire size ampacity chart is an essential tool for electricians and DIYers. It lists the safe current-carrying capacities for different wire gauges based on material and temperature. For instance, 14 AWG supports 15 amps, 12 AWG supports 20 amps, and 10 AWG supports 30 amps. Having this chart on hand simplifies the selection process for any electrical project. Remember, using a smaller wire than recommended can be hazardous and result in code violations.

Voltage Drop and Wire Length Considerations

Voltage drop occurs when electrical energy is lost as current travels through a wire, especially over long distances. The longer the wire, the greater the resistance and voltage loss. For a 30 amp circuit, if the distance exceeds 100 feet, you should upgrade from 10 AWG to 8 AWG wire. This helps maintain consistent power delivery and prevents equipment malfunction. Minimizing voltage drop improves energy efficiency and extends the lifespan of your electrical components.

How Temperature Affects Wire Capacity

Ambient temperature plays a major role in how much current a wire can carry safely. High temperatures increase resistance, which can reduce ampacity and cause overheating. For example, a 10 AWG wire rated for 30 amps at 75°F may only handle 25 amps in a hot environment. Always check temperature correction factors on ampacity charts before finalizing your wire choice. Proper ventilation and heat-resistant insulation help maintain safe operating conditions.

Common Applications for 30 Amp Circuits

Thirty-amp circuits are often used for heavy-duty electrical devices that draw more power than standard outlets can provide. Common applications include electric dryers, RV power hookups, water heaters, air compressors, and small welding machines. These appliances require stable current flow to operate efficiently. Installing a properly wired 30 amp circuit ensures these devices function safely without tripping breakers or overheating wires. Always verify each appliance’s electrical rating before connecting it to the circuit.

Choosing the Right Type of Wire Insulation

Wire insulation protects conductors from heat, moisture, and physical damage. For a 30 amp circuit, insulation types like THHN or THWN are commonly used due to their heat resistance and durability. If the circuit is installed outdoors or in wet locations, choose insulation rated for moisture protection. Using the correct insulation not only prevents electrical faults but also ensures long-term reliability. Always follow NEC guidelines when selecting wire insulation types for specific environments.

What Happens If You Use the Wrong Wire Size

Using the wrong wire size for a 30 amp circuit can lead to serious safety and performance issues. An undersized wire, such as 12 AWG, can overheat and melt its insulation, increasing the risk of fire. Oversized wire, while safer, may be more difficult to handle and costly. The key is to use the wire size that matches the circuit’s amperage rating and installation conditions. Always double-check your calculations before beginning any electrical project.

Safety Risks of Undersized Wires

Undersized wires are one of the most common causes of electrical failures. When a wire is too thin for the current it carries, it generates excessive heat. This can melt the insulation and cause sparks or short circuits. Over time, the wire may degrade, leading to power loss or even electrical fires. Always follow recommended gauge sizes for each amperage level to avoid these risks. Safety should always take priority over saving costs on smaller wire.

Is Oversized Wire a Problem?

Using an oversized wire for a 30 amp circuit is generally safe but may not always be practical. Larger wires are more expensive and harder to bend or fit into junction boxes. However, they can reduce voltage drop and improve performance in long runs. There’s no electrical danger in using thicker wire, but it might not be cost-effective for short circuits. Balance safety, efficiency, and budget when deciding on wire thickness for your installation.

How to Calculate the Correct Wire Gauge

Calculating the correct wire gauge for a 30 amp circuit involves considering current load, wire length, and material type. Copper wires carry current more efficiently than aluminum, so they can use smaller gauges. The formula for voltage drop can help determine if a thicker wire is needed for long runs. Always compare your results with an ampacity chart to ensure compliance with electrical codes. Accurate calculations help maintain performance, prevent overheating, and ensure electrical safety.

Factors That Influence Wire Gauge Selection

Several factors affect the choice of wire gauge, including distance, material, insulation type, and temperature. Longer circuits need thicker wires to minimize voltage drop. Copper offers better conductivity, while aluminum may require upsizing. Additionally, installation conditions such as conduit type and heat exposure can influence ampacity. Always consider these variables before finalizing your wire selection. A careful evaluation ensures that your 30 amp circuit performs efficiently and safely for years.

Wire Gauge Recommendations for Long-Distance Runs

When wiring a 30 amp circuit over a long distance, voltage drop becomes a critical concern. For wire runs longer than 100 feet, it’s advisable to use 8 AWG copper wire instead of 10 AWG. This ensures the connected equipment receives sufficient voltage without power loss. For aluminum wire, you may need to go up to 6 AWG. Always calculate voltage drop using length, current, and wire material to ensure safe and reliable power delivery over extended distances.

Electrical Code Requirements for 30 Amp Circuits

The National Electrical Code (NEC) sets the standard for safe electrical installations in the United States. For 30 amp circuits, the NEC requires a minimum of 10 AWG copper or 8 AWG aluminum wire. It also mandates proper grounding, circuit labeling, and breaker compatibility. Local jurisdictions may have additional requirements, so always check with your local building authority. Adhering to code ensures both safety and compliance with legal electrical standards.

Understanding the NEC (National Electrical Code) Guidelines

The NEC provides detailed guidance on wire sizing, insulation, grounding, and circuit protection. It’s updated regularly to reflect safety improvements and modern electrical demands. For a 30 amp circuit, the NEC’s ampacity tables specify that 10 AWG copper wire is sufficient under typical conditions. The code also defines derating factors for temperature, conduit fill, and voltage drop. Following NEC guidelines ensures your installation is both safe and future-proof.

Step-by-Step Process for Installing a 30 Amp Circuit

Installing a 30 amp circuit requires careful planning and adherence to safety protocols. First, turn off the main power supply to avoid electric shock. Measure and cut the appropriate length of wire, then strip and connect it to the breaker and outlet. Ensure all connections are tight and insulated properly. Label the circuit clearly on the panel for future reference. Testing the setup before use ensures everything operates correctly and safely.

Turning Off Power Before Installation

Before beginning any electrical work, always shut off power at the main breaker panel. This step prevents accidental shocks and ensures a safe workspace. Use a non-contact voltage tester to confirm that no current is flowing through the wires. Safety gloves and insulated tools are also essential during installation. Turning off the power not only protects you but also prevents damage to electrical components while connecting or adjusting wires.

Measuring and Cutting the Right Wire Length

Accurate measurement is key to a neat and efficient installation. Measure the total distance between the breaker, outlets, and appliances to determine the correct wire length. Always add a few extra inches for connections and adjustments. Cutting the wire too short can lead to loose or strained joints, which are unsafe. Once measured, use a wire cutter to make a clean, even cut to ensure a secure connection when terminating the wire ends.

Stripping and Preparing Wire Ends Correctly

Properly stripping wire ends ensures a strong electrical connection. Use a wire stripper to remove the insulation without nicking or damaging the metal conductor. Expose just enough copper to fit securely into the terminal or connector. Twist stranded wires gently to keep them neat and avoid fraying. Securely fasten each wire to its terminal using the correct screwdriver size. Good preparation reduces resistance and enhances the reliability of your circuit.

Connecting Wires to a 30 Amp Breaker Safely

When connecting wires to a 30 amp breaker, precision and safety are essential. Insert the stripped wire into the breaker terminal and tighten it securely to prevent loosening over time. Ensure that the wire insulation stops just outside the clamp to prevent exposed conductors. Follow color-coding standards: black or red for hot wires, white for neutral, and green or bare for ground. Double-check all connections before turning the power back on to avoid potential faults.

Grounding and Neutral Connections Explained

Grounding and neutral connections are essential parts of any safe electrical system. The ground wire provides a path for excess electricity to flow safely into the earth during a fault. The neutral wire completes the circuit by carrying current back to the panel. In a 30 amp circuit, the ground wire is typically bare or green, while the neutral is white. Ensuring proper grounding prevents electric shocks and equipment damage. Always connect these wires according to NEC color codes.

Testing Your 30 Amp Circuit After Installation

After wiring your 30 amp circuit, testing is a vital step to confirm everything is functioning correctly. Use a multimeter to check for continuity, proper voltage, and secure connections. Ensure that the breaker turns off and on smoothly without tripping unnecessarily. Plug in a compatible device to verify the circuit can handle the expected load. If any irregularities appear, turn off the breaker immediately and recheck your wiring. Testing helps ensure long-term safety and performance.

How to Read Wire and Cable Labels

Understanding wire labels is key to choosing the correct cable for a 30 amp circuit. Labels often include information like wire gauge (AWG), insulation type (THHN, NM-B), and temperature rating. For example, “10 AWG THHN 600V” means the wire is 10 gauge, suitable for up to 600 volts, and rated for high temperatures. Familiarizing yourself with these markings helps prevent mistakes and ensures compliance with electrical codes. Always verify labeling before installation.

Understanding Markings Like “10-2” and “10/3”

The markings “10-2” and “10/3” indicate the number of conductors within a cable. A “10-2” wire has one hot, one neutral, and a ground wire, while “10/3” includes two hot wires, one neutral, and a ground. For a 30 amp, 240-volt circuit, “10/3” is often used since it supports dual hot connections. Understanding these labels ensures you select the correct cable for your specific circuit type. Always check your appliance requirements before choosing the wire configuration.

Indoor vs. Outdoor Wire Options

Indoor and outdoor wires differ in insulation type and environmental resistance. For indoor use, NM-B (non-metallic sheathed) wire is common, offering flexibility and ease of installation. Outdoor circuits, however, require weather-resistant wires such as THWN or UF-B, which are protected against moisture and UV rays. Choosing the correct wire type prevents corrosion, damage, and short circuits. Always match the wire’s rating with the environmental conditions for reliable and safe performance.

How Conduit Type Affects Wire Selection

The type of conduit you use influences wire choice and installation method. Metal conduits like EMT or rigid steel provide excellent protection and grounding, while PVC conduits are lightweight and corrosion-resistant. Wires inside conduits should have insulation suitable for heat and moisture, such as THHN or THWN. Properly sized conduits allow wires to stay cool and prevent insulation damage. Selecting the right conduit ensures both safety and durability in 30 amp electrical systems.

Choosing Between Solid and Stranded Wire

Solid and stranded wires serve different purposes depending on flexibility and installation needs. Solid wire is a single conductor, ideal for stationary installations where movement is minimal, such as inside walls. Stranded wire, made up of multiple smaller strands, is more flexible and easier to route through tight spaces or conduits. For 30 amp circuits, both types can work, but stranded wire is preferred in dynamic or vibration-prone environments. Always ensure proper connections for either type.

Common Mistakes When Wiring a 30 Amp Breaker

Several mistakes can occur when wiring a 30 amp breaker, including using the wrong wire gauge, loose connections, or skipping the grounding step. Another common error is overloading the circuit with multiple high-power appliances. These mistakes can cause overheating, breaker trips, or even electrical fires. Always double-check your wire size, tighten all terminals, and follow NEC guidelines. Taking time to verify your work prevents costly and dangerous electrical failures.

How to Prevent Overheating in Electrical Circuits

Overheating in electrical circuits usually results from undersized wires, poor ventilation, or overloading. To prevent this, always use the correct wire gauge for the amperage and allow sufficient air circulation around cables and conduits. Avoid bundling too many wires tightly together, as it restricts heat dissipation. Regularly inspect outlets and connections for signs of wear or discoloration. Preventing overheating extends wire lifespan and keeps your 30 amp circuit safe and efficient.

Professional Tips for Safe Wire Installation

Professional electricians follow strict safety standards during installation. Always de-energize the panel before starting work, use insulated tools, and verify wire labeling. When routing wires, avoid sharp bends and ensure proper strain relief at connection points. Label each circuit clearly inside the breaker panel for future maintenance. Using junction boxes and connectors rated for the correct amperage further enhances safety. Following professional installation practices guarantees a dependable and hazard-free electrical system.

Can You Run a 30 Amp Breaker on 14 Gauge Wire?

No, you should never run a 30 amp breaker on 14 gauge wire. Fourteen-gauge wire is only rated for 15 amps, which is half the current a 30 amp breaker allows. Using this thin wire would cause it to overheat almost immediately, melting insulation and posing a serious fire hazard. Always use 10 AWG wire for 30 amps to stay within safe limits. Following proper wire sizing keeps your circuit code-compliant and safe from electrical damage.

Signs Your Wiring Is Incorrect or Unsafe

Incorrect or unsafe wiring often shows visible warning signs. Flickering lights, burning smells, hot outlets, or frequently tripping breakers indicate a problem. Loose connections or undersized wires can cause these issues, leading to voltage drops or overheating. Regular electrical inspections help identify problems early before they become dangerous. If you notice any of these signs, turn off power immediately and contact a qualified electrician to evaluate your wiring system.

Upgrading Older Circuits to Handle 30 Amps

Older homes often have circuits that were not designed to handle modern power demands. If you’re adding heavy appliances, upgrading to a 30 amp circuit may be necessary. This upgrade involves replacing the existing breaker, wiring, and possibly the outlet with components rated for 30 amps. It’s important to use the correct wire gauge (10 AWG copper) and follow all code requirements. Professional installation ensures your upgraded system operates safely and efficiently.

The Importance of Proper Load Calculation

Before installing a 30 amp circuit, calculating the total load is critical. Add up the wattage of all devices that will run on the circuit and divide by the voltage to find the current draw. The total should not exceed 80% of the breaker’s capacity for continuous use. For a 30 amp circuit, that’s about 24 amps of safe continuous load. Proper load calculation prevents overloads, tripped breakers, and potential electrical damage to connected equipment.

Tools Needed for Installing a 30 Amp Circuit

Having the right tools makes wiring safer and more efficient. You’ll need a voltage tester, wire stripper, screwdriver set, cable cutter, electrical tape, and a torque wrench. Safety equipment like insulated gloves and goggles is also essential. A fish tape can help pull wires through conduits, while a multimeter verifies connections. Using high-quality tools reduces the risk of mistakes and ensures that your 30 amp installation is done professionally and securely.

Consulting a Licensed Electrician for Verification

Even if you’re confident in your wiring skills, it’s smart to have a licensed electrician inspect your work. Electricians ensure your installation complies with the National Electrical Code and local regulations. They can verify breaker sizing, wire gauge, grounding, and connection tightness. Having professional verification gives peace of mind that your system is safe and reliable. In many areas, inspections are required before new circuits can be approved for use.

Comparing Wire Sizes for 20, 30, and 40 Amp Circuits

Different amperage circuits require different wire gauges to operate safely. A 20 amp circuit uses 12 AWG wire, a 30 amp circuit needs 10 AWG, and a 40 amp circuit typically requires 8 AWG. Choosing the right wire prevents overheating and voltage loss. Always check the manufacturer’s specifications and code charts when working with varying current loads. Proper comparison ensures each circuit delivers power efficiently and within safety standards.

Common Appliances That Require 30 Amp Circuits

Several household and industrial appliances need 30 amp circuits due to their high power demand. Examples include electric dryers, water heaters, RV hookups, and certain power tools. These devices often operate on 240 volts, which requires thicker wiring and a double-pole breaker. Installing the correct circuit size ensures stable performance and prevents nuisance tripping. Always check the manufacturer’s recommendations before connecting an appliance to ensure the circuit meets its amperage needs.

Conclusion

Selecting the correct wire gauge for a 30 amp circuit is one of the most important steps in electrical safety. Ten-gauge copper wire remains the standard choice for most applications due to its strength, conductivity, and reliability. Always consider distance, temperature, and material when planning your installation. Following the NEC guidelines ensures your wiring system operates safely and efficiently. With proper installation, a 30 amp circuit will provide years of stable, worry-free performance.

FAQs

Q: What size wire should I use for a 30 amp breaker?

A: Use 10 AWG copper wire or 8 AWG aluminum wire for most installations.

Q: Can I use 12 gauge wire for 30 amps?

A: No, 12 gauge wire is only rated for 20 amps.

Q: How far can I run 10 AWG wire for 30 amps?

A: Up to about 100 feet before voltage drop becomes an issue. Beyond that, use 8 AWG.

Q: Is copper better than aluminum wire?

A: Yes, copper has higher conductivity and better durability for most home circuits.

Can I use 8 AWG wire instead of 10 AWG for a 30 amp breaker?

Yes, 8 AWG wire can handle a 30 amp load and is sometimes used for longer wire runs to reduce voltage drop. While it’s thicker and more expensive, it provides extra safety margin, especially in high-temperature areas or long-distance circuits. However, for standard home applications, 10 AWG is sufficient and more cost-effective. Always ensure proper installation practices when using a larger gauge.

What type of insulation should I choose for a 30 amp wire?

Insulation depends on your installation environment. For indoor circuits, NM-B (non-metallic sheathed) wire is common. For outdoor or wet locations, use UF-B (underground feeder) or THWN wires rated for moisture and UV exposure. The insulation type protects the wire from heat, moisture, and abrasion while maintaining electrical safety. Always match insulation type with local electrical code requirements.

How do I calculate voltage drop for a 30 amp circuit?

Voltage drop depends on wire length, gauge, and load. The longer the wire, the higher the resistance and the more voltage is lost. For 30 amp circuits, try to keep voltage drop below 3% for efficiency. Using a larger gauge wire like 8 AWG for runs over 100 feet helps reduce voltage drop. Online calculators or electricians can provide precise calculations for your specific setup.

Can I install a 30 amp RV outlet with 10 AWG wire?

Yes, a 10 AWG copper wire is standard for most 30 amp RV outlets. It safely handles the current demand of RV appliances, including air conditioners and kitchen equipment. Make sure the breaker, wire, and outlet are all rated for 30 amps. Proper grounding and weatherproofing are also crucial for outdoor RV installations.

Is it safe to splice 10 AWG wire for a 30 amp breaker?

Splicing 10 AWG wire can be safe if done correctly using appropriate connectors and following NEC guidelines. Ensure tight, clean connections, and use wire nuts or crimp connectors rated for 30 amps. Poor splicing can cause overheating or fire hazards, so inspect all splices carefully. Avoid multiple splices in one section of a circuit to minimize risk.

How long can I safely run 10 AWG wire for a 30 amp circuit?

Typically, 10 AWG wire can run up to about 100 feet for a 30 amp circuit without significant voltage drop. If the circuit exceeds this length, consider upgrading to 8 AWG to maintain voltage and prevent overheating. Always account for both voltage drop and environmental conditions when planning long runs. This ensures efficient, safe power delivery.

Keep an eye for more latest news & updates on premiumtechy!