The correct size wire for a 100-amp service depends primarily on the material used and the installation type. For copper wiring, a 4 AWG or 3 AWG wire is typically sufficient, while aluminum wire requires a larger size such as 1 AWG or 1/0 AWG to handle the same load safely. Choosing the proper wire size ensures efficient power flow, reduces the risk of overheating, and complies with National Electrical Code (NEC) standards. Always consider both ampacity and distance before finalizing your selection.

For a 100-amp electrical service, the standard wire size is #4 AWG copper or #1 AWG aluminum, as recommended by NEC guidelines. The final choice can change based on distance, temperature, and installation type, with longer runs requiring larger wire to reduce voltage drop. Always follow local electrical codes and consult a licensed electrician to ensure safety and compliance.

In this article, we discuss the topic of “size wire 100 amp service“.

Understanding the Basics of 100 Amp Electrical Service

:max_bytes(150000):strip_icc()/sub-panels-for-additional-space-1152719-02-005eee12f5f94074916b97746345058d.jpg)

A 100-amp electrical service is commonly used in medium-sized homes, garages, and small commercial buildings. It provides adequate power for lighting, heating, and multiple appliances. This service includes a main breaker rated at 100 amps that controls the flow of electricity from the utility to the home’s distribution panel. Understanding the function of this service helps homeowners plan electrical layouts more effectively and prevents overloading circuits.

Why Wire Size Matters for a 100 Amp Circuit

Wire size directly affects how safely and efficiently electricity travels through a system. Undersized wires can overheat, cause voltage drops, and even start fires. Using the correct wire size for a 100-amp circuit ensures optimal power delivery and compliance with safety regulations. It also extends the life of connected appliances and prevents energy loss due to resistance. Proper sizing is essential for every installation, whether residential or commercial.

The Standard Wire Sizes for 100 Amp Service

For a 100-amp service, copper wire sizes typically range from 4 AWG to 2 AWG, while aluminum wire sizes range from 2 AWG to 1/0 AWG. These sizes are recommended based on NEC ampacity charts for 75°C and 90°C insulation ratings. In installations where the distance exceeds 100 feet, upsizing the wire to reduce voltage drop may be necessary. Using the standard sizes ensures compliance, performance, and safety in all types of wiring systems.

Copper vs Aluminum Wire for 100 Amp Service

Copper wire is known for its high conductivity, durability, and resistance to corrosion. It can carry more current through a smaller diameter compared to aluminum. However, aluminum is lighter, less expensive, and easier to install for longer runs. The main trade-off is that aluminum requires larger gauges to achieve the same ampacity. For homeowners, both options are safe if installed correctly and connected using compatible terminals and anti-oxidation paste.

Recommended Copper Wire Size for 100 Amp Panel

According to NEC standards, the recommended copper wire size for a 100-amp panel is 4 AWG when the wire is rated for 75°C insulation. If the run is particularly long, upgrading to 3 AWG or even 2 AWG may be necessary. Copper wires are more efficient in carrying current over shorter distances with minimal voltage loss. Always check temperature ratings and consult local codes to ensure compliance before final installation.

Recommended Aluminum Wire Size for 100 Amp Panel

For aluminum wiring, the recommended wire size for a 100-amp panel is 1 AWG or 1/0 AWG. Aluminum has higher resistance than copper, so a thicker gauge is needed to carry the same load safely. These wire sizes are ideal for main service feeders and subpanels. It’s crucial to use aluminum-rated connectors and apply anti-oxidant compound to prevent corrosion and maintain conductivity.

What AWG Wire Is Needed for 100 Amp Service?

In American Wire Gauge (AWG) standards, a 100-amp service typically requires #4 AWG copper or #1 AWG aluminum wire. However, these values can vary depending on voltage, temperature, and conduit type. For underground or outdoor installations, you may need a larger size to compensate for environmental factors. Using the correct AWG wire size is key to maintaining proper voltage and ensuring safety compliance under NEC guidelines.

NEC Guidelines for Wire Size in 100 Amp Service

The National Electrical Code (NEC) provides clear tables outlining ampacity limits for different wire materials and insulation types. For a 100-amp service, Table 310.16 of the NEC lists 4 AWG copper and 1 AWG aluminum as acceptable conductors. The code also emphasizes ambient temperature correction factors and conduit fill requirements. Always refer to the latest NEC edition to ensure your installation meets modern electrical standards.

Factors That Affect Wire Size Selection for 100 Amp Service

Several factors influence the correct wire size for a 100-amp service: wire material, length of the run, temperature rating, and type of insulation. The longer the distance, the thicker the wire required to prevent voltage drop. Ambient temperature also affects current capacity — higher temperatures reduce ampacity. Considering these factors ensures safe and efficient operation while avoiding costly rewiring in the future.

How Distance Impacts Wire Size for 100 Amp Service

Distance plays a major role in determining wire size because voltage drop increases as the wire run lengthens. For every 100 feet, voltage can drop by 3–5% depending on wire type. To counter this, electricians often increase the wire gauge one or two sizes larger. For instance, a 150-foot run might use 2 AWG copper instead of 4 AWG. Proper sizing maintains efficiency and protects sensitive equipment from low-voltage damage.

Voltage Drop Considerations for 100 Amp Wire Runs

Voltage drop occurs when electrical current loses energy due to resistance in the conductor. The NEC recommends a maximum voltage drop of 3% for branch circuits and 5% for total feeder systems. To minimize voltage drop, choose thicker conductors or shorten the wire run where possible. Regular testing with a voltmeter after installation helps ensure the system performs within acceptable limits.

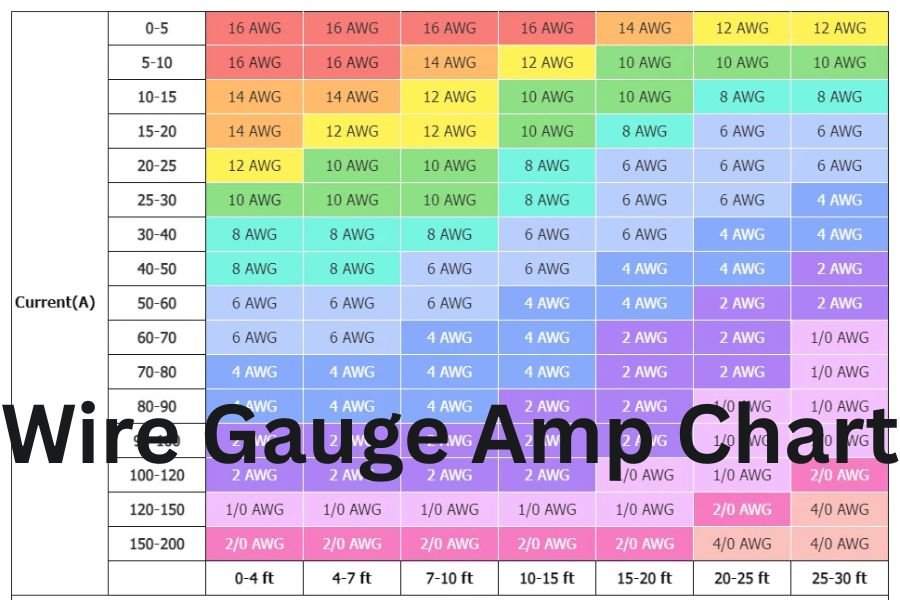

Wire Size Chart for 100 Amp Service Based on Distance

A wire size chart simplifies selection by matching distance to proper wire gauge. For example, up to 50 feet requires 4 AWG copper or 2 AWG aluminum; 100 feet may need 3 AWG copper or 1 AWG aluminum; and beyond 150 feet, 2 AWG copper or 1/0 AWG aluminum is ideal. Using a chart ensures accurate planning and reduces the risk of under-sizing conductors in large installations.

Choosing Between 2 AWG and 4 AWG for 100 Amp Circuits

Both 2 AWG and 4 AWG copper wires can be used for 100-amp circuits depending on distance and load type. 4 AWG works well for short runs under 50 feet, while 2 AWG is better for longer distances or high-load equipment. The choice often depends on cost, flexibility, and installation conditions. Always prioritize performance and safety over price when making this decision.

Is #2 AWG Copper Enough for 100 Amp Service?

Yes, #2 AWG copper wire is more than sufficient for 100-amp service and offers extra safety margin for longer runs. It carries up to 115 amps at 75°C and maintains excellent voltage stability. Many electricians prefer #2 AWG for subpanels located far from the main panel to avoid voltage drop. Although it costs more, its durability and reliability make it a worthwhile investment.

Is #1 AWG Aluminum Enough for 100 Amp Service?

#1 AWG aluminum wire is suitable for a 100-amp service as per NEC recommendations. It provides ample current capacity while remaining lightweight and affordable. However, aluminum connections require careful handling to prevent oxidation. Proper torque, anti-oxidant paste, and aluminum-rated terminals must be used to maintain long-term safety and performance.

Ground Wire Size Requirements for 100 Amp Service

For grounding a 100-amp service, the NEC specifies 8 AWG copper or 6 AWG aluminum grounding conductors. Ground wires provide a safe path for electrical faults and prevent shock hazards. They must connect securely to both the service panel and the grounding electrode system. Correct grounding not only ensures code compliance but also enhances protection against lightning and power surges.

How to Calculate the Right Wire Size for 100 Amp Load

Calculating the correct wire size involves three key elements: amperage, distance, and voltage drop. Use the formula:

Voltage Drop = (Current × Length × Resistance per foot) ÷ 1000.

This helps determine if a larger conductor is needed. Online calculators can simplify this process, ensuring your chosen wire meets both ampacity and efficiency standards. Always round up to the next larger size for safety.

Differences Between Main Panel and Subpanel Wiring

A main panel receives power directly from the utility, while a subpanel is fed from the main. The key difference lies in grounding and neutral connections — in subpanels, the neutral and ground must remain isolated. Wire size also differs depending on the load and distance. Using the proper size wire for each ensures smooth operation and avoids electrical code violations.

Wire Size for 100 Amp Subpanel in a Detached Garage

When feeding a detached garage, the wire size for a 100-amp subpanel depends on distance and material. For short runs under 50 feet, #4 AWG copper or #1 AWG aluminum works well. If the garage is 100 feet away, upsize to #2 AWG copper or 1/0 AWG aluminum to prevent voltage drop. Always run four conductors — two hots, one neutral, and a ground — and install a separate ground rod at the detached building per NEC rules.

Correct Wire Size for 100 Amp Subpanel 100 Feet Away

For a 100-foot run, voltage drop becomes significant. To stay below 3% loss, use at least #3 AWG copper or #1 AWG aluminum conductors. Underground feeders should be placed in PVC conduit rated for burial. Applying these sizes ensures the subpanel delivers full power without straining breakers or equipment. Proper sizing also reduces heat buildup and improves system longevity.

Wire Size for 100 Amp Subpanel 200 Feet Away

At 200 feet, resistance doubles, so you must upsize again. Electricians commonly use #1 AWG copper or 2/0 AWG aluminum wire for such long runs. This larger gauge offsets the voltage drop and maintains steady current. Though costlier, it prevents under-voltage damage to motors, HVAC units, and sensitive electronics. Always consult a licensed electrician to verify final calculations.

The Best Wire Types for 100 Amp Electrical Service

Several wire types meet NEC standards for 100-amp circuits: THHN/THWN-2 for conduit, SER for service entrance, UF-B for direct burial, and USE-2 or URD for underground runs. Each type offers unique insulation properties and temperature ratings. Select a wire type that matches your installation location — indoor, outdoor, or underground — to ensure safety and longevity.

THHN and THWN-2 Wires for 100 Amp Circuits

THHN and THWN-2 wires are popular for conduit installations thanks to their heat and moisture resistance. THHN is rated for dry locations up to 90 °C, while THWN-2 handles wet or damp environments. For a 100-amp service using copper THWN-2, choose #4 AWG for short runs or #2 AWG for longer distances. Always verify ampacity ratings before pulling wires through conduit.

XHHW and XHHW-2 Wires for 100 Amp Service

XHHW and XHHW-2 cables feature cross-linked polyethylene (XLPE) insulation with superior heat and abrasion resistance. They’re ideal for industrial or commercial settings where high temperatures are common. For a 100-amp load, use #4 AWG copper or #1 AWG aluminum XHHW-2. Their higher temperature rating means better ampacity and longevity than basic PVC-insulated cables.

SER Cable for 100 Amp Service Installations

Service Entrance ( SER ) cable is frequently used for feeding subpanels and main panels indoors. It contains two hot conductors, one neutral, and a bare ground. For a 100-amp service, 2-2-2-4 SER aluminum or 4-4-4-6 SER copper is common. SER must not be buried directly but can run through conduit between structures. It’s flexible, affordable, and easy to install for panel feeders.

USE-2 and URD Aluminum Wires for 100 Amp Service

USE-2 and URD (Underground Residential Distribution) cables are designed for direct burial without conduit. A typical 100-amp installation uses 2-2-2-4 URD aluminum wire, rated for 600 volts. These cables are moisture-resistant and UV-protected, making them ideal for outdoor feeders to detached structures. Always check local codes before direct burial to ensure compliance.

UF-B Underground Cable for 100 Amp Direct Burial

UF-B (Underground Feeder) cable is a solid option for direct burial in residential yards. It combines multiple conductors within a moisture-resistant sheath and can handle up to 90 °C. For a 100-amp circuit, #2 AWG copper UF-B is recommended. It must be buried at least 24 inches deep and protected with warning tape or conduit at entry points to avoid damage.

Using MC Cable for 100 Amp Indoor Applications

Metal-clad (MC) cable features an aluminum armor that provides physical protection and a built-in ground conductor. For 100-amp indoor feeds, choose #3 AWG or #2 AWG copper MC cable depending on distance. It’s approved for commercial and residential use where conduit is impractical. However, MC is not suitable for wet locations or direct burial.

Insulation Types and Temperature Ratings for 100 Amp Wires

Wire insulation determines how much heat a conductor can withstand safely. Common types include THHN (90 °C dry), THWN-2 (90 °C wet/dry), and XHHW-2 (90 °C wet/dry). Selecting the right insulation ensures the wire maintains ampacity without deteriorating. Always match the wire’s temperature rating with the breaker and panel specifications to avoid derating.

Understanding Ampacity and Its Role in Wire Sizing

Ampacity is the maximum current a wire can carry continuously without exceeding its temperature limit. It varies by wire material, gauge, and insulation. For example, #4 AWG copper THHN has an ampacity of 95 amps at 60 °C and 115 amps at 75 °C. Accurate ampacity calculations ensure that the wire can handle the load without overheating or tripping breakers.

Common Mistakes When Choosing 100 Amp Wire Size

Homeowners often underestimate distance or ignore voltage drop, leading to undersized wires. Others mix copper and aluminum without using proper connectors. Using the wrong insulation or failing to follow local codes are other frequent errors. These mistakes can cause overheating, energy loss, and fire hazards. Always consult a professional before final installation.

How to Avoid Voltage Drop in Long 100 Amp Runs

To reduce voltage drop, use shorter runs, larger gauge wires, and tight connections. For every 100 feet of run, consider increasing wire size by one step. Regular maintenance and inspection of terminals also help prevent energy loss. In critical applications, install voltage regulators to maintain consistent supply across the entire system.

100 Amp Service Wire Size for Residential Homes

Most medium-sized homes operate safely on a 100-amp service. The recommended wire sizes are #4 AWG copper or #1 AWG aluminum for main feeders. This setup supports lighting, kitchen appliances, and HVAC systems. Homes with electric heating or EV chargers may require an upgrade to 150 or 200 amps for added capacity and future expansion.

Wire Size for 100 Amp Service in Mobile Homes

Mobile homes commonly use 100-amp services due to their compact load requirements. For a typical installation, use #2 AWG copper or 1/0 AWG aluminum wire. Mobile home feeder cables must be rated for wet locations and buried in conduit. Ensure a solid grounding system and bond the neutral only at the service disconnect to avoid ground faults.

Correct Wire Size for 100 Amp Service in RV Parks

In RV parks, a 100-amp service panel may feed multiple pedestals or an individual coach with heavy appliances. Use #3 AWG copper or #1 AWG aluminum wire to maintain consistent voltage across long runs. Outdoor-rated conduit and weatherproof boxes are mandatory. Proper wire sizing prevents tripped breakers and protects expensive RV equipment from power fluctuations.

Wire Size for 100 Amp Service in Commercial Buildings

Commercial buildings often require longer runs and higher ambient temperatures, so upsizing is common. For a 100-amp commercial feed, use #3 AWG copper or 1/0 AWG aluminum XHHW-2 cable. These cables handle heat and corrosion better than residential-grade wires. Always follow NEC Article 310 and local codes for conduit fill and derating adjustments.

Typical Applications of 100 Amp Electrical Panels

:max_bytes(150000):strip_icc()/sub-panels-for-additional-space-1152719-hero-d464dd917e004ffc9f2d10e28d466dca.jpg)

A 100-amp panel is ideal for small to medium homes, detached garages, workshops, and small businesses. It can power lighting circuits, receptacles, HVAC, and appliances efficiently. In industrial settings, it often serves as a subpanel for specialized equipment. Understanding your load requirements ensures the panel is neither overloaded nor under-utilized.

When to Upgrade from 100 Amp to 200 Amp Service

If you’re adding electric vehicles, large HVAC units, or new appliances, a 200-amp service upgrade may be necessary. Signs include frequent breaker trips and voltage fluctuations. Upgrading doubles capacity, allowing for future expansion without rewiring the entire system. Consult an electrician to assess current load and panel capability before proceeding.

Cost Difference Between Copper and Aluminum Wire for 100 Amp Service

Copper wire is more expensive than aluminum due to its higher conductivity and durability. On average, copper costs 2–3 times more per foot than aluminum. For instance, a 100-foot run of #4 AWG copper might cost over $250, while #1 AWG aluminum costs closer to $100. While copper offers lower resistance and better longevity, aluminum remains popular for budget-conscious projects. Both are safe if installed correctly and paired with compatible connectors.

How to Install 100 Amp Service Wire Safely

Proper installation starts by de-energizing the circuit and verifying all components meet NEC standards. Use the correct size conduit for your chosen wire type and ensure all bends have adequate radius to avoid damage. Connectors and lugs must be rated for the wire material — copper or aluminum. Secure the conductors firmly into the breaker and neutral bus bar, torque to specification, and inspect for loose strands. Always test continuity and insulation resistance before energizing the system.

Safety Tips for Handling 100 Amp Service Wiring

When dealing with high-amperage wiring, safety is critical. Always turn off the main breaker and verify no voltage is present using a multimeter. Wear insulated gloves and safety glasses to prevent shock or arc flash injuries. Keep wires organized in conduit to prevent chafing and overheating. Avoid mixing copper and aluminum without proper anti-oxidation paste and connectors. If uncertain, hire a licensed electrician — improper handling can cause severe electrical hazards.

Local Electrical Codes Affecting 100 Amp Wire Size

Local jurisdictions often modify NEC guidelines to suit regional conditions. Some areas require specific burial depths, conduit materials, or wire types based on soil or climate. Always check with your building department before installation. Using non-approved materials may fail inspection or void insurance coverage. Compliance ensures not only safety but also peace of mind during future property transactions.

Consulting an Electrician for Proper Wire Sizing

Determining the correct wire size for a 100-amp service isn’t always straightforward. Professional electricians use load calculations, NEC tables, and voltage drop formulas to select proper conductors. They also verify temperature ratings, conduit fill, and grounding requirements. Consulting a licensed electrician prevents mistakes, ensures code compliance, and guarantees safe operation. Even DIY installations should be inspected before final connection to the utility line.

How Ambient Temperature Affects Wire Size for 100 Amp Service

Temperature has a major influence on wire ampacity. In hotter environments, conductors heat up faster, reducing their current-carrying capacity. For instance, a wire rated for 100 amps at 30°C may only handle 90 amps at 40°C. The NEC provides temperature correction factors to account for these variations. Always adjust wire size accordingly — oversizing by one or two gauges in hot climates helps maintain safety margins.

Future Expansion Considerations for 100 Amp Service Wiring

If you plan to install additional circuits, EV chargers, or power-hungry equipment, consider upsizing your conductors during the initial installation. For example, running 2 AWG copper instead of 4 AWG provides capacity for future upgrades. It’s far cheaper to install larger wires upfront than to rewire later. Planning ahead ensures your electrical system remains adaptable as your power needs evolve.

The Best Practices for Grounding a 100 Amp Panel

A well-grounded electrical system protects both people and equipment. The NEC requires connecting the panel’s ground bus to a grounding electrode system — typically two 8-foot copper rods spaced six feet apart. Use 8 AWG copper or 6 AWG aluminum grounding conductors for a 100-amp service. Tighten all connections and bond the water pipe if applicable. Proper grounding ensures fault currents have a safe path to earth, preventing shocks and equipment damage.

Common Problems Caused by Incorrect Wire Size

Using wires that are too small can lead to overheating, nuisance tripping, and equipment failure. Undersized wires also cause voltage drop, reducing appliance efficiency and lifespan. In extreme cases, insulation may melt, creating a serious fire hazard. Oversized wires, on the other hand, can be difficult to work with and may not fit terminals properly. Correct wire sizing ensures optimal system balance, efficiency, and safety.

Final Recommendations for Choosing the Right Size Wire for 100 Amp Service

To summarize, the best wire size for a 100-amp service is #4 AWG copper or #1 AWG aluminum under normal conditions. Increase the gauge for longer distances or higher temperatures. Always verify compliance with the latest NEC standards and local building codes. For underground or outdoor applications, select the appropriate insulation type such as XHHW-2, THWN-2, or URD. Finally, consult a licensed electrician before making permanent connections. The right wire size guarantees a safe, efficient, and future-proof electrical installation.

Advanced Tips for Installing 100 Amp Service Wiring

Even after choosing the correct conductor, installation technique determines performance and longevity.Always begin by planning the entire route from the meter to the main panel. Use wide-radius conduit bends to reduce stress on the insulation. Label both ends of every conductor clearly—future maintenance becomes much easier.During pulling, avoid twisting or kinking the wire because that damages insulation and increases resistance. After termination, torque all lugs to the manufacturer’s specification using a calibrated wrench. Finally, document every measurement and keep a record of wire sizes and breaker ratings for inspection purposes.

Inspecting and Testing Your 100 Amp Installation

Once wiring is complete, perform a continuity test and insulation-resistance test before energizing the system.Check that neutral and ground conductors are isolated in subpanels and bonded in the main service panel.Measure voltage at the panel lugs to confirm that the supply delivers full 240 V (or 120/240 V split phase) without drop.Thermal cameras are useful for detecting hotspots once power is on. Record all readings in a logbook; these benchmarks help identify deterioration later.

Energy Efficiency Considerations

Correct wire sizing also affects energy efficiency. Oversized conductors reduce resistance losses, saving electricity over time.While the initial cost of thicker wire may be higher, reduced heat loss can pay off in long-term savings—especially on long feeder runs.

Pairing proper wire size with energy-efficient appliances, LED lighting, and smart load control can lower overall energy bills without sacrificing power capacity.

Environmental and Sustainability Aspects

Copper is fully recyclable and maintains conductivity even after reuse, making it environmentally friendly despite its higher price.Aluminum production has a larger energy footprint, but its light weight lowers shipping emissions.When planning your installation, consider local recycling options and buy wire from manufacturers who use recycled metal.Sustainable choices not only meet performance standards but also support greener construction practices.

Troubleshooting Voltage Drop and Heating Issues

If you notice lights dimming when appliances start, or breakers tripping frequently, the issue might be voltage drop.First, verify the wire gauge and distance match NEC recommendations. Check every termination for loosened screws or corrosion, particularly with aluminum conductors.Use a clamp meter to measure current on each phase; uneven loads can also cause heating.Upgrading wire gauge or balancing circuits typically resolves these problems and restores stable power delivery.

Periodic Maintenance for 100 Amp Electrical Systems

A well-installed service still needs routine inspection.Once a year, de-energize the panel and check for discoloration, loose connections, and corrosion. Tighten lugs as needed and clean dust or debris.Inspect outdoor conduits and junction boxes for moisture ingress or insect nests.

Replacing worn grommets and sealing openings prevents future failures. Proactive maintenance extends system life and ensures continued code compliance.

Upgrading Components Alongside Wire Sizing

When upgrading to a 100-amp service, don’t overlook other components such as the main breaker, meter base, and grounding electrodes.Older panels may not accept modern copper or aluminum conductor sizes. Replace outdated equipment with UL-listed, code-approved parts.

Installing a surge protector at the main panel safeguards electronics against lightning and grid surges, complementing the benefits of proper wire sizing.

Integrating Renewable Energy with a 100 Amp Service

Homeowners adding solar panels or wind turbines should evaluate service capacity carefully.A 100-amp service can accommodate small renewable systems, but the interconnection must include a back-feed breaker and proper wire gauge from the inverter.In many cases, upgrading to 150 A or 200 A service provides headroom for additional solar arrays or battery storage systems.Consult both your electrician and utility provider before finalizing the design.

Documentation and Labeling Best Practices

Accurate labeling simplifies maintenance and troubleshooting.Each feeder should display its ampacity, material, and destination near the panel.Use weather-resistant tags or heat-shrink labels on outdoor wiring.Keep a printed single-line diagram showing breaker assignments, wire gauges, and grounding locations.Good documentation also helps future electricians verify compliance without guessing conductor sizes.

Key Takeaways

- Correct Wire Size: Use #4 AWG copper or #1 AWG aluminum for standard 100 A service.

- Account for Distance: Upsize conductors to counter voltage drop on long runs.

- Match Insulation Type: Choose THWN-2, XHHW-2, or URD depending on location.

- Follow NEC and Local Codes: Always confirm requirements before installation.

- Safety First: De-energize, test, and torque connections properly.

- Plan for Growth: Install slightly larger wires to allow future upgrades.

- Maintain Regularly: Annual inspection prevents hidden faults.

Conclusion

Choosing the correct size wire for a 100 amp service is one of the most crucial decisions in any electrical installation. The right wire ensures safety, efficiency, and code compliance, while the wrong one can lead to overheating, voltage drops, or even fire hazards.For most residential applications, #4 AWG copper wire or #1 AWG aluminum wire is suitable for a 100-amp main panel. However, other factors such as distance, wire type, insulation, ambient temperature, and installation environment can affect your final choice.

Always follow the National Electrical Code (NEC) standards and local building codes. It’s also strongly recommended to consult a licensed electrician to verify your calculations, especially for longer wire runs or specialized installations such as subpanels, detached garages, or underground wiring.By choosing the correct wire size and installing it properly, you ensure that your 100-amp electrical service runs safely, efficiently, and reliably for years to come. Proper planning today can save you from costly electrical issues and upgrades tomorrow.

FAQs

1. What size wire do I need for a 100 amp service?

For most standard installations, you’ll need #4 AWG copper wire or #1 AWG aluminum wire. These sizes meet NEC requirements for a 100-amp circuit and are suitable for most residential and small commercial applications.

2. Does the distance affect the wire size for 100 amp service?

Yes, absolutely. If your wire run exceeds 100 feet, voltage drop becomes a concern. In that case, you may need to upsize your wire to #2 AWG copper or 1/0 AWG aluminum to maintain efficiency and prevent overheating.

3. Can I use aluminum wire instead of copper for 100 amp service?

Yes, aluminum wire is acceptable as long as it meets code and is sized correctly—typically #1 AWG aluminum for 100 amps. However, aluminum requires special connectors and anti-oxidant compounds to prevent corrosion and ensure safe conductivity.

4. What type of wire insulation should I choose for 100 amp service?

The most common insulation types are THHN/THWN-2, XHHW, SER, and USE-2.

- Use THHN/THWN-2 for indoor conduit installations.

- XHHW-2 and SER are great for above-ground service entrances.

- USE-2 and URD cables are preferred for underground service.

5. What is the correct ground wire size for a 100 amp service?

The recommended grounding wire size is #8 AWG copper or #6 AWG aluminum. The grounding conductor connects your panel to the grounding electrode (like a ground rod) to prevent electrical shock and improve safety.

6. Can I run a 100 amp subpanel off my main panel?

Yes, you can. Many homeowners install a 100 amp subpanel in detached garages, workshops, or basements. Ensure that the wire size matches the distance:

- Up to 50 ft: #4 AWG copper / #1 AWG aluminum

- 100–150 ft: #2 AWG copper / 1/0 AWG aluminum

- 200 ft or more: 1/0 AWG copper / 2/0 AWG aluminum

7. What happens if I use a wire that’s too small for a 100 amp service?

Using a smaller wire can cause excessive heat buildup, voltage loss, and fire risk. Undersized wires can’t safely carry the current and may cause breaker trips or melted insulation. Always size your wire correctly based on ampacity charts and NEC codes.

8. Can I bury 100 amp service wire underground?

Yes. For underground installations, use UF-B cable or USE-2/URD wire rated for direct burial. The trench should typically be 18–24 inches deep, depending on local code requirements, and protected by conduit if necessary.

9. How do I calculate voltage drop for my 100 amp service?

Voltage drop depends on wire material, length, and load. As a rule of thumb, try to keep voltage drop under 3%. Use online voltage drop calculators or consult an electrician to determine the exact wire size for your specific distance and setup.

10. Do I need a permit to install a 100 amp service?

Yes. Most local jurisdictions require a permit and inspection for service upgrades or new installations. This ensures the work meets NEC safety standards and local utility requirements before it’s energized.

Keep an eye for more latest news & updates on premiumtechy!