Electric fences are an efficient way to control livestock, protect property, and ensure safety. However, a common question that often arises is: does the ground wire need to be insulated? The answer depends on the design of your fence and how the grounding system works. Understanding the science and best practices behind it can help you build a more reliable and shock-effective electric fence.

No, an electric fence ground wire usually does not need to be insulated because it must stay in direct contact with the earth to complete the circuit.Insulation would block the flow of electricity and reduce the fence’s shock effectiveness.Ground wires are designed to safely carry voltage back into the soil.However, if the wire runs above ground or through a structure, insulation may help prevent accidental contact.

We talk about “does electric fence ground wire need to be insulated” in this article.

Understanding Electric Fence Systems

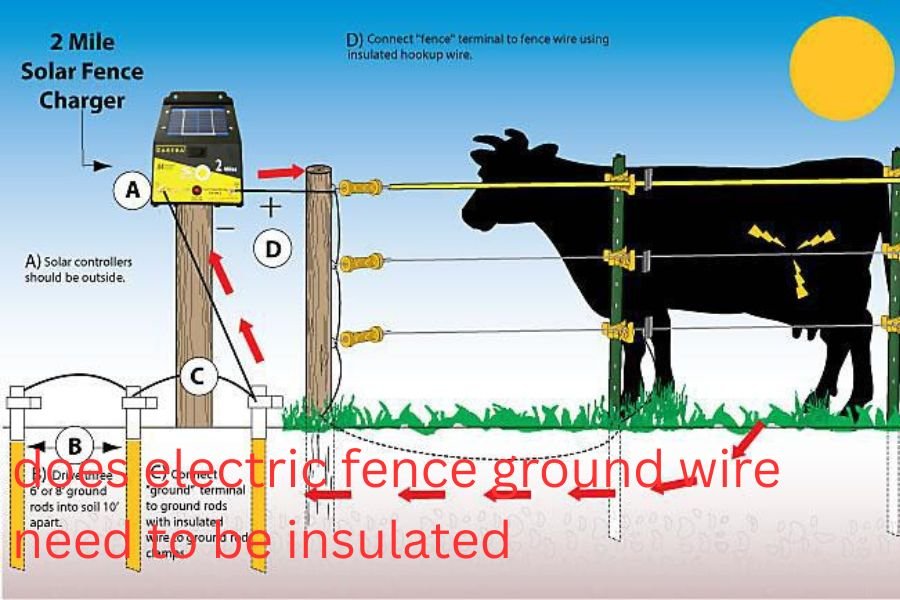

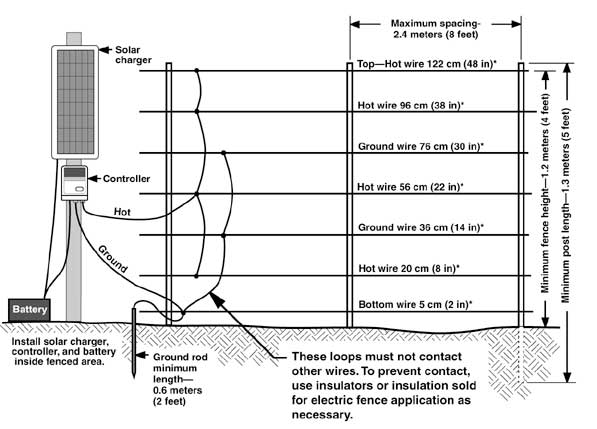

An electric fence operates as a complete circuit that delivers short pulses of high voltage to deter animals. The system includes an energizer, hot wires, insulators, and grounding components. When an animal touches the live wire, electricity travels through its body to the soil, completing the circuit through the grounding system. Without a proper ground, even the most powerful energizer becomes ineffective.

The Role of the Ground Wire in an Electric Fence

The ground wire acts as the return path for the electric current. It ensures that when an animal completes the circuit by touching a hot wire, the current flows through the soil and back to the energizer. This return path is essential for maintaining voltage strength and system reliability. In short, the ground wire is the backbone of the entire fence’s operation.

What Does Insulation Mean in Electric Fencing?

Insulation refers to covering a wire with a non-conductive material to prevent electrical contact with unintended surfaces. In fencing systems, insulation is typically applied to hot wires to stop electricity from leaking into fence posts, soil, or vegetation. Ground wires, however, are intended to maintain contact with the earth — which is why they rarely need insulation.

Difference Between Hot and Ground Wires

Hot wires carry the current from the energizer and must be insulated from the fence posts. Ground wires, on the other hand, serve as a return path to the energizer. They are often bare or uninsulated to ensure proper conductivity with the soil. Understanding this difference helps prevent installation mistakes that reduce fence effectiveness.

Does the Ground Wire Carry Voltage?

Under normal circumstances, the ground wire does not carry voltage because it’s not a live conductor. However, if there is poor grounding or a short circuit, it can carry a small residual current. If this happens, it’s a sign that your grounding system needs inspection, cleaning, or reinforcement with additional ground rods.

Why Insulation Might Not Be Needed for Ground Wires

Insulating a ground wire prevents it from making direct contact with the soil, which interrupts the circuit and weakens the shock. Ground wires must stay bare and exposed to the ground to allow current to flow freely. Therefore, in most cases, insulation would do more harm than good when it comes to grounding wires.

Situations Where Insulating a Ground Wire May Help

In rare cases, insulation can be beneficial. When ground wires pass through buildings, gates, or areas with metal objects, insulation helps prevent unwanted electrical contact. It also protects humans and animals from accidental shocks if the wire runs above the ground or near accessible areas.

Types of Wires Used in Electric Fences

Different types of wire are used depending on the fence’s purpose. High-tensile steel is durable and weather-resistant, aluminum provides excellent conductivity, and copper offers strong performance but can corrode when in contact with certain metals. Choosing the right wire type ensures optimal efficiency and long-term durability.

Bare vs. Insulated Wire: What’s the Difference?

Bare wires are uncoated conductors that allow electricity to move freely between the wire and its surroundings, perfect for grounding applications. Insulated wires, coated in plastic or rubber, restrict electrical flow to prevent loss or shock. For electric fences, use bare wire for ground circuits and insulated wire for live or long underground runs.

How Grounding Affects Fence Efficiency

Grounding directly impacts the fence’s shock strength. Without a strong grounding system, electricity cannot complete its circuit, and animals will feel a weaker pulse. A properly installed ground ensures that even minimal contact with a hot wire delivers a consistent, effective shock — vital for containment and deterrence.

Proper Grounding Techniques for Electric Fences

To achieve proper grounding, install at least three galvanized ground rods, each 6–8 feet long, spaced 10 feet apart. Connect them with heavy gauge wire using corrosion-resistant clamps. Place the rods in consistently moist soil, away from buildings and water lines, to ensure reliable conductivity all year long.

How Many Ground Rods Do You Need?

The number of rods depends on your energizer’s power and soil type. A general rule is one rod for every joule of energizer output. For example, a 5-joule energizer needs five ground rods. More rods mean a stronger and more reliable current, especially in dry or rocky areas.

Common Grounding Mistakes to Avoid

Frequent grounding mistakes include using too few rods, placing rods too close together, or installing them in dry, sandy soil. Another common issue is mixing metal types, which can cause corrosion. Always use proper connectors, and ensure the rods are driven deep into consistently moist soil.

Materials for Electric Fence Grounding

Galvanized steel is the most popular grounding material because it resists corrosion and conducts electricity well. Copper is also effective but can cause galvanic corrosion when used with steel components. Always use compatible metals and avoid rusted or oxidized materials, as they increase electrical resistance.

Can Poor Grounding Cause Weak Fence Shocks?

Yes, inadequate grounding is the number one cause of weak or no shock. Without a complete return path to the energizer, electricity fails to circulate properly. This results in low voltage readings on the fence tester and ineffective containment. A solid ground system restores the fence’s full power and reliability.

Testing the Grounding System

Testing ensures your system is working efficiently. To check, use a voltmeter between the last ground rod and the soil while the fence is running. Readings above 300 volts indicate a poor ground. Adding more rods or improving soil moisture usually fixes the issue quickly and easily.

Can Ground Wires Touch Each Other?

Yes, ground wires can be connected together as part of the same grounding network. In fact, linking them helps create a stronger return path. However, they should never touch hot wires or energized sections of the fence, as that could cause a short circuit or electrical leakage.

What Happens If Ground Wire Is Insulated Improperly?

If the ground wire is accidentally insulated or covered, it can’t make proper contact with the soil. This breaks the electrical circuit and weakens the fence’s power output. Improper insulation is one of the most common causes of ineffective electric fences, especially among DIY installations.

Outdoor Conditions That Affect Grounding

Soil moisture, temperature, and weather conditions all affect grounding. Dry, sandy, or frozen ground increases resistance, while moist, mineral-rich soil improves conductivity. Regularly checking the ground system during seasonal changes ensures consistent fence performance throughout the year.

Rust and Corrosion in Ground Wires

Rust and corrosion increase resistance in metal wires, reducing the current’s flow. Ground rods and connections should be checked regularly for signs of rust. Cleaning or replacing corroded components restores proper conductivity and maintains consistent electrical performance across the fence.

Maintenance Tips for Grounding Systems

Regular maintenance prevents voltage loss and ensures reliability. Clean all wire connections annually, check for corrosion, and tighten clamps. Keep the soil around the rods damp during dry months, and replace any damaged wires. A well-maintained grounding system guarantees peak performance year-round.

How Moisture Affects Electric Fence Grounding

Moisture plays a major role in conductivity. Wet soil allows electrical current to flow easily, while dry soil resists it. During droughts, sprinkling water around ground rods or using a saltwater solution can improve contact and keep your fence running efficiently.

Ground Wire Placement: How Deep Should It Be?

Ground rods should be driven at least 6–8 feet into the ground for best results. The deeper the rod, the better the contact with moisture and minerals that enhance conductivity. Shallow installations often lead to weak grounding and inconsistent performance during dry spells.

Can You Use Regular Electrical Wire for Fencing?

Regular household electrical wire isn’t suitable for electric fences because it’s not designed for outdoor or high-voltage use. Fence wires must handle voltage spikes, weather exposure, and tension. Always use specialized fence wire or insulated underground cable for safe, long-term operation.

Choosing Between Aluminum and Copper Ground Wires

Aluminum wires are lightweight, affordable, and resist corrosion well. Copper, while more conductive, can cause electrochemical reactions when used with galvanized steel rods. For most fences, galvanized wire remains the best choice due to its balance of conductivity and durability.

Does Soil Type Matter for Grounding?

Yes, soil type greatly affects conductivity. Clay and loamy soils retain moisture, making them ideal for grounding. Sandy or rocky soils, on the other hand, resist electricity. If your area has poor soil, adding more rods or keeping the soil damp will improve grounding.

Clay vs. Sandy Soil: Which Is Better for Grounding?

Clay soil retains water and minerals, creating excellent conditions for grounding. Sandy soil drains quickly, increasing resistance and reducing performance. In sandy regions, bury rods deeper or use more of them to achieve proper contact with the earth.

Can You Mix Wire Types in a Fence System?

It’s possible, but not always ideal. Mixing metals like copper and steel can lead to corrosion, reducing performance over time. Stick to one wire type across your entire system to ensure consistent conductivity and prevent maintenance issues later on.

What Are the Risks of Poor Insulation?

Poor insulation on hot wires can lead to power leaks and accidental grounding. This drains energy from the system and can create hazards for animals or people. Always inspect insulators regularly and replace any cracked or damaged ones to maintain fence safety.

Insulators vs. Grounding Rods: Key Differences

Insulators prevent current from escaping the hot wire, while grounding rods create a safe path for the current to return to the energizer. Both components serve opposite but equally vital roles. A well-insulated system with a strong ground ensures maximum efficiency.

Does the Ground Wire Need to Be Buried?

In most setups, the ground wire doesn’t need to be fully buried unless it’s running long distances underground. For those cases, using insulated underground cable is essential. Buried wires stay protected from damage and maintain a cleaner, safer installation.

Lightning Protection and Grounding

Proper grounding protects your fence from lightning strikes. Installing a lightning diverter and additional ground rods provides a safe path for high-voltage surges. This prevents damage to the energizer and prolongs the lifespan of your entire fencing system.

Ground Wire Safety Precautions

Always disconnect power before working on your electric fence. Use protective gloves and insulated tools. Keep ground wires away from water lines, pipes, and buried cables to avoid accidents. Safety precautions ensure the fence remains both effective and secure.

Can Insulated Ground Wire Increase Resistance?

Yes, insulation can increase resistance in ground wires because it blocks direct contact with the earth. This prevents electricity from flowing freely through the soil. Bare wire allows for a stronger, more reliable grounding system, ensuring consistent fence operation.

How to Troubleshoot Electric Fence Ground Issues

If your fence isn’t performing well, test the voltage at different points along the fence and at the grounding rods. Low readings indicate poor grounding. Add more rods, clean existing ones, or improve soil moisture until the voltage stabilizes across the system.

Can You Run Ground Wires Above Ground?

Yes, ground wires can run above ground as long as they don’t pose a safety risk or interfere with equipment. However, they should remain in contact with the earth where grounding occurs. Use insulated cable if the wire crosses gates or driveways.

Ground Return Path in Electric Fences Explained

The ground return path is the route electricity takes from the animal, through the soil, to the energizer’s ground terminal. A clear, low-resistance path is crucial for strong performance. If this path is interrupted, the fence becomes weak or stops working.

Should You Use Insulated Wire for Long Ground Runs?

When running ground wire over long distances or under gates, use insulated underground cable. This prevents accidental contact with other metals and minimizes power loss. Once the wire reaches the grounding rods, it should be bare to ensure good soil contact.

The Science Behind Electrical Conductivity

Electrical conductivity is the ability of a material to allow electricity to flow. Metals like copper and aluminum are excellent conductors, while dry soil is a poor one. Understanding this principle helps you design a fence that maintains a strong and consistent charge.

Environmental Impact of Improper Grounding

Poor grounding can waste electricity and increase maintenance costs. Corroded metals or excessive chemical use in soil can also harm the environment. Using durable, eco-friendly materials and maintaining good grounding helps protect both your property and the ecosystem.

Signs Your Fence Ground System Isn’t Working Properly

Common signs include weak shocks, low voltage readings, or animals escaping easily. You may also see sparks at connections or fluctuating voltmeter results. Addressing these issues early prevents costly repairs and ensures your fence operates at full capacity.

DIY Tips for Better Electric Fence Performance

Keep vegetation away from hot wires, regularly test voltage, and maintain clean connections. Install rods in damp soil and check all insulators monthly. Simple maintenance habits can extend your fence’s lifespan and ensure maximum efficiency.

Professional Installation vs. DIY Grounding

DIY installation can save money but requires attention to detail. Professionals, however, bring expertise and specialized tools to ensure long-term reliability. If you’re managing a large system or dealing with poor soil, professional grounding is worth the investment.

Cost of Insulated vs. Non-Insulated Ground Wire

Bare galvanized wire is affordable and ideal for most ground setups. Insulated wire costs more but is useful for underground or indoor runs. Balancing both types according to your fence layout ensures efficiency without unnecessary expense.

Can Animals Interfere With Ground Wires?

Animals rarely disturb ground wires, but they can damage exposed cables or connections near the surface. Protect above-ground sections with conduit or insulation to prevent accidental chewing or displacement by livestock.

Seasonal Maintenance for Grounding Systems

Grounding systems require attention throughout the year. In dry seasons, keep rods moist; in winter, ensure they’re deep enough to avoid frozen soil. Seasonal checks prevent voltage drops and extend the life of your electric fence system.

How to Keep Your Ground Rods Working Efficiently

Clean ground rods annually with sandpaper or a wire brush to remove corrosion. Tighten connections, ensure clamps are secure, and keep soil around the rods damp. Proper maintenance ensures strong conductivity and reliable performance.

Myths About Ground Wire Insulation

One popular myth is that insulating ground wires improves performance — this is false. Ground wires need direct soil contact to function effectively. Another misconception is that fewer rods are fine for small systems, but even small setups need solid grounding.

Conclusion

In conclusion, the ground wire of an electric fence generally should not be insulated. Its purpose is to maintain contact with the soil to complete the electrical circuit. However, insulated wire is useful when the ground wire must travel above ground or through structures. A proper grounding system, maintained regularly, ensures your fence remains powerful, reliable, and safe.

FAQs

1. Does the ground wire on an electric fence need insulation?

No, the ground wire doesn’t need insulation because it must stay in contact with the soil to complete the electric circuit.

2. What happens if I insulate the ground wire?

Insulating the ground wire prevents it from connecting properly to the earth, weakening the fence’s shock power.

3. When should I use insulated wire on an electric fence?

Use insulated wire only when running the wire above ground, through gates, or near buildings to prevent accidental contact.

4. How important is grounding for an electric fence?

Grounding is critical—it ensures the electrical current returns to the energizer efficiently for a strong and consistent shock.

5. Can poor grounding affect fence performance?

Yes, poor grounding is the most common cause of weak or inconsistent shocks in electric fence systems.

6. Can I use regular electrical wire for grounding an electric fence?

It’s not recommended. Regular electrical wire may corrode or have poor conductivity; use galvanized or aluminum wire designed for fencing.

7. How deep should ground rods be for an electric fence?

Ground rods should typically be at least 6 to 8 feet deep to ensure a strong electrical connection with the soil.

8. Does soil type affect electric fence grounding?

Yes, soil with higher moisture or clay content provides better grounding than dry, sandy soil.

9. How many ground rods do I need for my fence?

Most fences require at least three ground rods, spaced about 10 feet apart for optimal performance.

10. Can insulated wire increase resistance in an electric fence?

Yes, insulated wire can slightly increase resistance if it’s not rated for high voltage, which can weaken the fence’s output.

Keep an eye for more latest news & updates on premiumtechy!