A 50-amp wire size refers to the thickness of electrical wire needed to safely carry 50 amperes of current without overheating. Every wire has a limit to how much electricity it can handle, and the right gauge prevents fires, energy loss, and equipment damage. In most cases, a 50-amp circuit uses 6-gauge copper wire or 4-gauge aluminum wire, but the exact size depends on distance and voltage. Understanding this term helps homeowners and technicians choose the right cable for the job and stay within electrical-code standards.

For a 50-amp circuit, the correct wire size is typically 6 AWG copper or 4 AWG aluminum, chosen based on distance, voltage, and installation conditions. Using the proper gauge prevents overheating, reduces voltage drop, and ensures appliances run safely and efficiently. Always follow NEC guidelines and consider upsizing the wire for long runs or continuous heavy loads to maintain safety and performance.

In this article, we discuss the topic of “50 amp wire size“.

Why Wire Size Matters for 50 Amp Circuits

Choosing the correct wire size is one of the most important safety steps in any electrical project. If a wire is too small, it can overheat and melt its insulation, creating fire hazards. Oversized wire, on the other hand, can make installation difficult and unnecessarily expensive. A 50-amp circuit usually powers high-demand appliances like ranges, dryers, or RV hookups, so precision matters. The correct wire size ensures efficient current flow, prevents voltage drop, and extends the life of connected devices.

The Role of the National Electrical Code (NEC) in Wire Sizing

The NEC sets nationwide standards that electricians follow to determine safe wiring practices. These codes outline how much current each wire gauge can carry depending on material type and insulation temperature rating. For a 50-amp circuit, the NEC table 310.16 lists the appropriate conductor sizes for copper and aluminum under various conditions. Following the NEC keeps installations compliant with building inspections and insurance policies. It’s the backbone for any safe electrical system in homes or businesses.

Understanding Amps, Volts, and Wire Gauge

Electricity flows like water through pipes—the amps are the amount of flow, the volts are the pressure, and the wire gauge is the pipe’s diameter. A larger current (amps) needs a wider wire to move smoothly without resistance. Wire gauge numbers run opposite of thickness: a smaller AWG number means a thicker wire. When you know how these three factors work together, selecting wire for a 50-amp circuit becomes simple math instead of guesswork.

What Size Wire Do I Need for a 50 Amp Circuit?

Most 50-amp circuits require 6-gauge copper wire for short runs under 100 feet. If the distance is longer, a thicker wire may be needed to offset voltage drop. Aluminum wire can also be used, but it requires a 4-gauge size because aluminum conducts electricity less efficiently than copper. Always verify your exact setup—voltage, distance, and temperature—before buying cable. When in doubt, use the next larger wire gauge to stay on the safe side.

Copper vs. Aluminum: Which Is Better for 50 Amps?

Copper wire is the industry favorite because it conducts electricity better, resists corrosion, and handles bending during installation without cracking. Aluminum, however, is lighter and more affordable, making it common in longer feeder lines. For a 50-amp load, both metals can work when installed correctly. Copper’s 6-gauge rating supports 55 amps safely, while aluminum needs to jump to 4 gauge. The final choice depends on cost, distance, and whether the wire runs indoors or outdoors.

Recommended 50 Amp Wire Size According to NEC Standards

Under the NEC 310.16 table, a 6 AWG copper conductor with 60 °C insulation is rated for 55 amps, perfectly matching a 50-amp breaker. A 4 AWG aluminum wire handles up to 65 amps under similar conditions. These ratings assume typical residential temperatures and conduit installation. Always confirm insulation type—THHN, NM-B, or UF-B—since each has a slightly different ampacity rating. Staying aligned with NEC recommendations ensures long-term safety and legal compliance.

50 Amp Wire Size Chart (Copper and Aluminum Comparison)

A quick look at a comparison chart makes choosing easier. For copper: 6 AWG = 55 amps, 4 AWG = 70 amps. For aluminum: 4 AWG = 65 amps, 2 AWG = 90 amps. This chart assumes standard 75 °C insulation and short distances. If your circuit runs over 100 feet, you may need to go one gauge thicker to prevent voltage loss. These numbers simplify selection while giving a visual guide to balance cost and efficiency.

Minimum and Maximum Wire Gauge for 50 Amps

The minimum safe wire gauge for a 50-amp circuit is 6 AWG copper or 4 AWG aluminum. Using anything smaller risks overheating under load. There’s technically no maximum limit, but extremely thick wires are harder to bend and connect. Installers sometimes choose 4 AWG copper if the run is long or conditions are hot. The goal is to match wire gauge with circuit demand and installation practicality, not simply go larger for no reason.

Understanding AWG (American Wire Gauge) for 50 Amp Circuits

AWG is the standardized numbering system for electrical wire sizes in North America. It assigns numbers to specific diameters so everyone—from electricians to manufacturers—speaks the same language. For instance, 6 AWG copper has a diameter of about 0.162 inches and can handle around 55 amps. The AWG scale ensures consistency between products, helping homeowners pick the right size without confusion. Recognizing these numbers saves time and avoids costly mistakes during installation.

How Distance Affects 50 Amp Wire Size

As electricity travels through wire, it meets resistance that causes voltage to drop. The longer the wire, the greater the loss. To keep voltage within 3 % of its original value, you may need to upsize your wire one or two gauges. For example, a 50-foot run might use 6 AWG copper, while a 150-foot run could need 4 AWG. Ignoring distance can cause appliances to run inefficiently or motors to burn out faster than expected.

Voltage Drop and Its Impact on Wire Performance

Voltage drop happens naturally, but too much can shorten appliance life or make heating elements weaker. A well-sized wire keeps voltage consistent across the circuit. The NEC suggests staying within a 3 % drop for branch circuits and 5 % total for feeders. If your 50-amp line powers a workshop tool or RV, even small drops can affect performance. Using a thicker wire is the simplest fix for maintaining full power.

50 Amp Wire Size for 240V Circuits

A 240-volt circuit delivers higher voltage than a standard 120-volt outlet and is common for large appliances such as ovens or welders. For a 50-amp 240-volt setup, 6-gauge copper wire is the usual recommendation because it can safely carry the current without overheating. Aluminum conductors should be 4-gauge to provide the same performance. Always double-check that your breaker and receptacle are rated for 240 V; mismatched components can lead to tripping or damage.

50 Amp Wire Size for 120V Circuits

Although 50-amp circuits are rarely used at 120 V, some workshop tools or RV configurations may run on that voltage. Because lower voltage requires more current to deliver the same power, the wire size remains the same—6 AWG copper or 4 AWG aluminum. The real consideration is ensuring that both hot and neutral conductors are properly balanced and grounded. Proper connections reduce voltage loss and keep the circuit stable during heavy load cycles.

50 Amp Wire Size for RV Hookups

RV hookups often require a 50-amp service to power air conditioners, microwaves, and outlets simultaneously. For short runs between the main panel and pedestal, 6-gauge copper wire provides excellent reliability. If the run exceeds 100 feet, upgrading to 4-gauge helps prevent voltage drop that could stress the RV’s systems. Outdoor-rated cable with UV and moisture protection, such as THWN or UF-B, is essential for campground or backyard installations.

50 Amp Wire Size for Hot Tubs and Spas

Hot tubs draw continuous current for heaters and pumps, making wire size crucial. A 50-amp hot-tub circuit generally uses 6-gauge copper with GFCI protection for safety near water. The conduit and fittings must also be weather-resistant since outdoor spas face moisture and temperature swings. When distance exceeds 75–100 feet, a thicker 4-gauge conductor keeps voltage steady so heating elements and jets work efficiently without strain.

50 Amp Wire Size for Electric Dryers

Most residential dryers use 30 amps, but commercial or high-capacity units may require a 50-amp connection. For these, 6 AWG copper wire ensures enough current capacity for heating elements and motors. The receptacle should match a 14-50R configuration, and connections must include both hot wires, a neutral, and a ground. Oversizing the wire slightly helps maintain efficiency and prevents breaker trips during long drying cycles.

50 Amp Wire Size for EV Chargers

Electric-vehicle charging stations frequently operate on 50-amp circuits to deliver fast, Level 2 charging. A dedicated 6-gauge copper circuit minimizes energy loss during overnight charging sessions. When the charger is installed outdoors, use conduit-protected THHN or THWN wire rated for moisture and heat. For longer distances from the panel, stepping up to 4 AWG maintains proper voltage, ensuring that the car charges safely and quickly each time.

50 Amp Wire Size for Welders

Welders demand large amounts of power during start-up and continuous operation. Many 240-volt welding units specify a 50-amp breaker, making wire choice critical. Using 6-gauge copper wire provides consistent power flow, preventing overheating of internal components. Aluminum wire may work for permanent shop installations if sized at 4 AWG and connected with antioxidant compound. Always follow the welder’s manual for exact current ratings and cable length recommendations.

50 Amp Wire Size for Air Conditioners

Central air-conditioning units sometimes require a 50-amp circuit, especially in larger homes. Because these systems operate for long hours, wire insulation and conductor size must handle continuous heat. Copper 6 AWG conductors rated at 75 °C or higher keep performance steady. For outdoor condensers, use UV-resistant conduit and weather-tight fittings. Proper sizing prevents nuisance breaker trips during hot weather when the compressor draws peak current.

How to Calculate Proper 50 Amp Wire Size

To find the right wire size, multiply current (amps) by voltage (volts) to estimate total wattage, then account for distance and allowable voltage drop. A common method uses online calculators or NEC tables. For instance, a 240-volt 50-amp circuit at 100 feet may need the next larger gauge to stay within a 3 % drop. Temperature rating and conduit fill also affect the final choice. Calculating before purchase ensures safety and efficiency.

NEC 125% Rule Explained for 50 Amp Circuits

The NEC requires that continuous loads be calculated at 125 % of their rating. That means a device drawing 40 amps continuously should be wired on a circuit rated for 50 amps. This buffer prevents wires and breakers from running at full capacity all the time, reducing heat buildup and wear. Applying the 125 % rule keeps your installation compliant and extends the life of both conductors and electrical devices connected to the circuit.

Common Mistakes When Choosing 50 Amp Wire

One of the most common mistakes people make is assuming all wires labeled for 50 amps are the same. In reality, factors such as distance, insulation type, and installation conditions can change what size is appropriate. Using household extension cable instead of proper rated wire is another dangerous error. Some DIYers also forget to match wire size with breaker capacity, which can cause tripping or overheating. Always double-check your wire gauge and application before installation.

Safety Risks of Using the Wrong Wire Size

Using the wrong wire size can lead to serious safety hazards. A wire that’s too small for the current may overheat, melt insulation, and spark fires behind walls. If the wire is too large, it can create loose connections that generate resistance and heat over time. Improperly sized conductors also cause voltage drops that stress appliances. Following the proper sizing chart and local electrical codes is the best way to avoid expensive and dangerous outcomes.

What Happens If Your Wire Is Too Small?

When a wire is too small for a 50-amp load, electrical resistance rises sharply, converting electricity into unwanted heat. This heat can gradually damage the wire jacket, weaken terminations, and even ignite flammable materials nearby. The circuit breaker might not trip immediately, making the danger hard to detect until damage has occurred. It’s always safer to oversize slightly rather than risk using undersized conductors for heavy electrical loads.

What Happens If Your Wire Is Too Large?

Using a larger wire than required won’t cause electrical hazards, but it can create installation challenges. Thick wires are harder to bend, fit into outlets, and connect to breakers. They also cost more per foot. If you’re working in tight spaces or conduits, excessive wire size can make pulling cables nearly impossible. For this reason, electricians balance efficiency and practicality, choosing the smallest gauge that still safely meets the current demand.

50 Amp Circuit Breaker Requirements

Every 50-amp circuit must include a properly rated breaker to protect wiring and connected devices. A double-pole 50-amp breaker is standard for 240-volt systems, while single-pole breakers are used in rare 120-volt cases. The breaker must match both the wire gauge and the appliance specifications. Using a smaller breaker will cause unnecessary tripping, while an oversized breaker may allow wires to overheat before tripping, posing a fire risk.

Matching Circuit Breaker Size to Wire Gauge

Circuit breakers and wire gauges go hand in hand. For a 50-amp breaker, the wire must be at least 6 AWG copper or 4 AWG aluminum according to NEC standards. Never install a 50-amp breaker on 8-gauge wire, as it’s only rated for 40 amps. Matching them ensures that if something goes wrong, the breaker trips before the wire overheats. Always check manufacturer recommendations and verify compatibility between breaker and conductor materials.

How to Read Cable Labels for 50 Amp Wire

Cable labels include essential information like gauge size, conductor material, insulation type, and temperature rating. For example, “6 AWG THHN Cu 600V” tells you it’s 6-gauge copper with THHN insulation rated up to 600 volts. Reading these details helps ensure you’re using the right product for your 50-amp circuit. Knowing how to decode wire markings also prevents confusion between similar-looking cables that may have very different ampacity ratings.

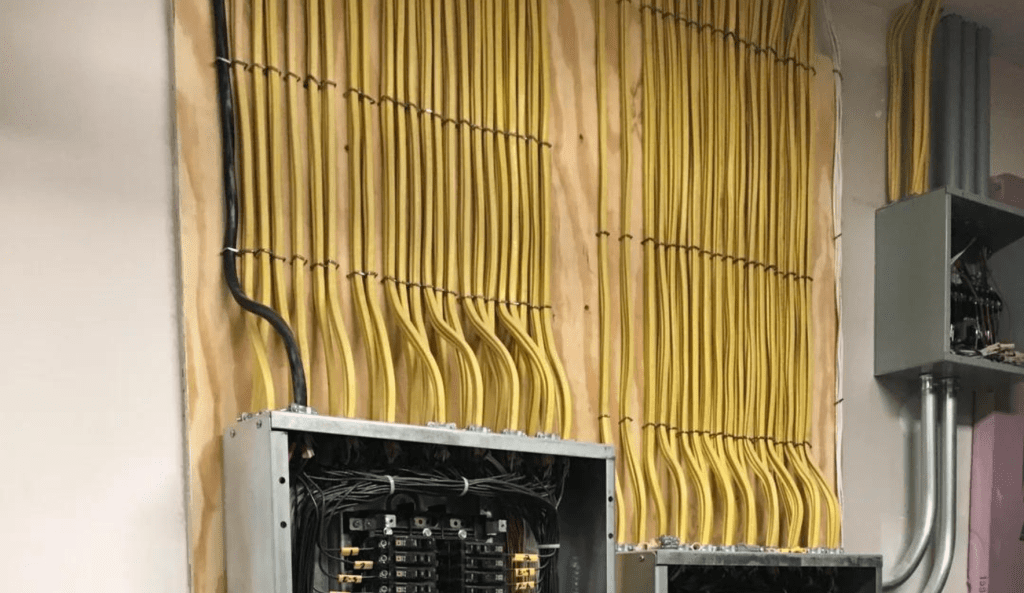

Types of Wire Used for 50 Amp Circuits (THHN, NM-B, UF-B, etc.)

Different projects require specific wire types. THHN is common in conduit for indoor or commercial use; it handles high temperatures well. NM-B, often called Romex, is designed for dry indoor walls. UF-B is made for underground installations and resists moisture. For outdoor or exposed areas, THWN or direct-burial cables are preferred. Choosing the correct type ensures the wire insulation withstands environmental stress while maintaining full current-carrying ability.

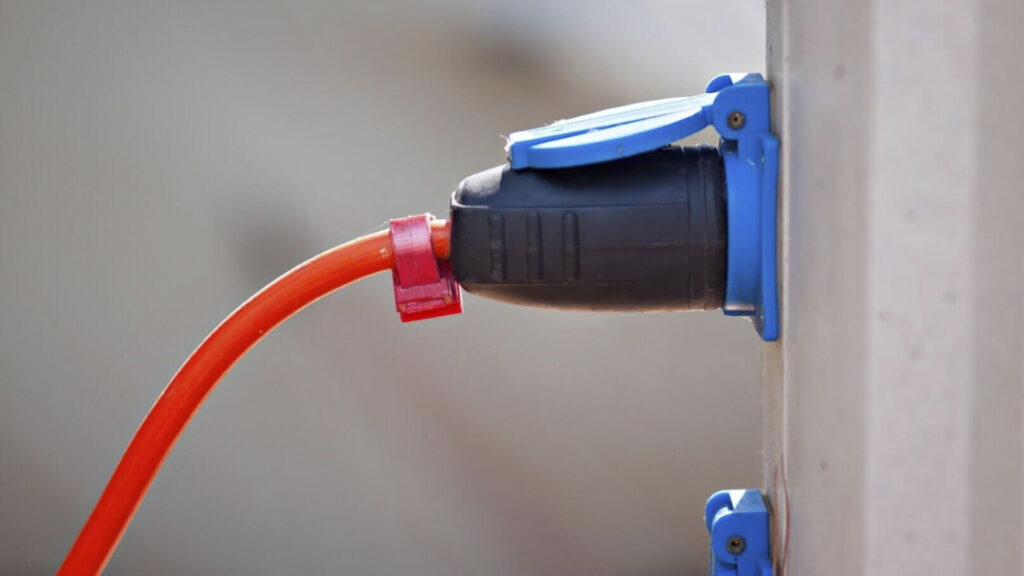

Indoor vs. Outdoor 50 Amp Wire Options

Indoor wiring generally uses NM-B or THHN conductors in conduit, depending on whether it’s hidden behind walls or surface-mounted. Outdoor wiring needs stronger protection from sun, rain, and temperature changes. THWN, UF-B, or SE-R cables are popular for exterior setups because they’re moisture-resistant and durable. Always check local code for burial depth and conduit type when running wires outdoors. Matching wire insulation to the environment ensures long-term reliability.

50 Amp Wire Size for Underground Installations

Underground circuits require wires that resist moisture and physical damage. UF-B or THWN conductors inside PVC conduit are common solutions for 50-amp underground runs. The burial depth usually ranges from 18 to 24 inches, depending on conduit type. Because underground runs are often long, upsizing one gauge—like using 4 AWG copper instead of 6 AWG—helps reduce voltage drop. Sealing all junction boxes prevents water infiltration that could corrode connections over time.

Conclusion

Selecting the correct 50 amp wire size is critical for both safety and efficiency in any electrical project. Using the right gauge, material, and insulation ensures that your appliances and systems operate reliably without risk of overheating or fire. Copper and aluminum are both viable options, but copper provides better conductivity while aluminum may be more cost-effective for longer runs.

Factors such as voltage, distance, installation environment, and breaker compatibility all play a key role in determining the ideal wire. By following NEC guidelines, checking voltage drop, and consulting a licensed electrician when necessary, you can create a safe, durable, and future-proof 50 amp electrical setup that protects your home, equipment, and family. Proper planning and attention to detail in wire sizing not only prevent hazards but also improve the performance and longevity of your electrical system.

FAQs

1. What size wire do I need for a 50 amp circuit?

For most 50 amp circuits, 6 AWG copper wire or 4 AWG aluminum wire is recommended. If the run is long, you may need to go up one gauge to reduce voltage drop. Always check NEC guidelines and your appliance requirements.

2. Can I use aluminum wire instead of copper for a 50 amp circuit?

Yes, aluminum wire can be used, but it must be larger than copper due to lower conductivity. Typically, 4 AWG aluminum is used in place of 6 AWG copper. Connections must be properly prepared to prevent oxidation.

3. How does distance affect the 50 amp wire size?

Longer wire runs increase resistance, which can lead to voltage drop. For runs over 100 feet, it’s recommended to increase the wire gauge to maintain proper voltage and prevent overheating.

4. What type of wire should I use outdoors or underground?

For outdoor or underground installations, use moisture-resistant wire types like UF-B, THWN, or THHN inside conduit. These wires are designed to handle temperature changes and water exposure.

5. What are the risks of using the wrong wire size for 50 amps?

Using a wire that is too small can overheat, melt insulation, and cause fire hazards. Using a wire that is too large is not dangerous but can be costly and difficult to install in tight spaces.

6. Do I need a special breaker for a 50 amp circuit?

Yes, you should use a 50-amp circuit breaker that matches the wire gauge. Double-pole breakers are used for 240V circuits, while 120V circuits are less common. The breaker protects the wire from overcurrent and prevents overheating.

7. Can I install a 50 amp circuit myself?

While small electrical projects may be DIY-friendly, a 50 amp circuit is high power and carries significant risks. It’s strongly recommended to hire a licensed electrician to ensure proper sizing, connections, and code compliance.

8. What appliances typically need a 50 amp circuit?

Common appliances include electric dryers, ovens, hot tubs, EV chargers, welders, central air conditioners, and RV power connections. Any appliance with a continuous high power demand may require a dedicated 50 amp circuit.

9. How do I future-proof my 50 amp circuit?

To future-proof your system, consider slightly upsizing your wire to handle voltage drops and potential appliance upgrades. Use high-quality materials, follow NEC guidelines, and ensure your breaker and conduit can support future modifications.

10. How can I test my 50 amp circuit for safety?

After installation, use a multimeter to check voltage at the outlet, and ensure no excessive voltage drop occurs under load. Confirm that the breaker trips correctly under fault conditions. Always consult a licensed electrician for final inspection.

Keep an eye for more latest news & updates on premiumtechy!