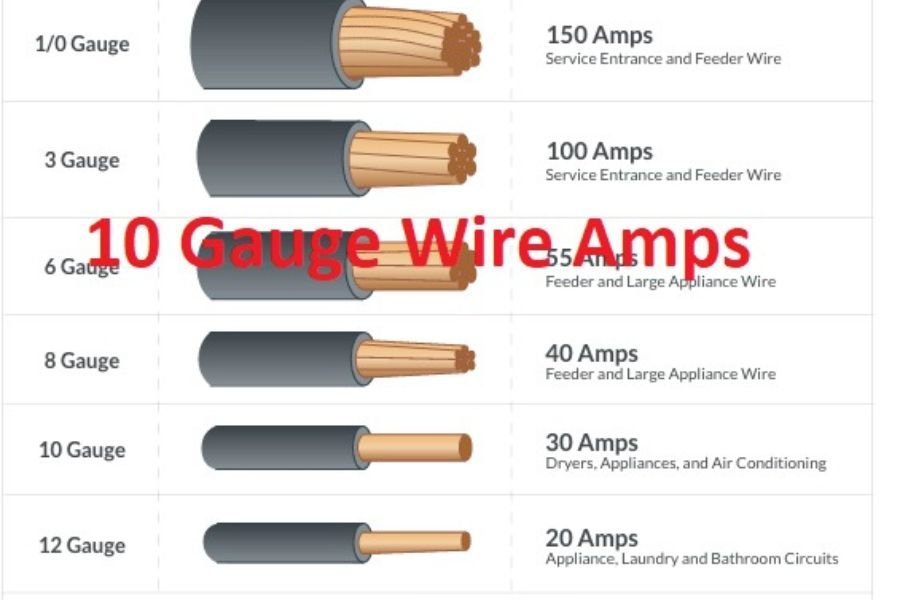

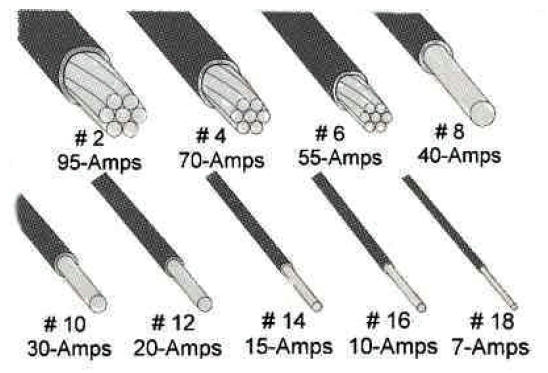

The ampacity of 10 gauge wire refers to the maximum amount of electrical current the wire can safely carry without overheating or creating a fire hazard. Ampacity varies depending on insulation type, conductor material, temperature rating, and installation environment. In general, copper 10 AWG wire handles more amps than aluminum due to better conductivity and lower resistance. The National Electrical Code (NEC) sets clear guidelines outlining ampacity values under different temperature ratings to ensure safe usage. Understanding these ratings is essential for selecting the right wire size for appliances, circuits, and electrical installations.

10-gauge wire ampacity depends on conductor material, insulation type, and installation conditions. In most residential setups, 10 AWG copper is safely rated for 30 amps, while 10 AWG aluminum is limited to about 25 amps due to higher resistance. Although higher-rated insulation (like THHN at 90°C) allows more current, NEC rules require breaker sizing based on the lowest-rated component to ensure safety.

In this article, we discuss the topic of “10 gauge wire amps“.

How Many Amps Can 10 Gauge Copper Wire Handle?

A 10 gauge copper wire typically handles 30 amps at 60°C, 35 amps at 75°C, and 40 amps at 90°C, depending on the insulation type. Copper’s superior conductivity allows it to carry more current with less heat buildup compared to aluminum. These amp ratings are standardized in the NEC and used for residential, commercial, and industrial wiring applications. Copper remains the preferred choice for high-load circuits because of its durability, high melting point, and lower voltage drop. When used correctly, 10 AWG copper provides consistent performance and safety in demanding electrical systems.

How Many Amps Can 10 Gauge Aluminum Wire Handle?

Aluminum 10 AWG wire carries fewer amps than copper because aluminum has higher electrical resistance and generates more heat. Typically, 10 gauge aluminum handles 25 amps at 60°C, 30 amps at 75°C, and 35 amps at 90°C. These ratings make it suitable for circuits where loads are moderate rather than heavy-duty. While aluminum is cost-effective and lightweight, its lower ampacity requires careful consideration during installation. Electricians often upsize aluminum conductors to match copper performance. Proper termination, anti-oxidation compound, and torque settings are essential when using aluminum to avoid overheating or loose connections.

Amp Rating of 10 Gauge Wire by Temperature Rating

Temperature rating plays a major role in determining how many amps a 10 gauge wire can carry safely. Wires with 60°C insulation have the lowest ampacity due to heat limitations. At 75°C, the ampacity increases because the insulation can withstand higher temperatures. The highest ampacity is found at 90°C insulation, where materials like THHN or XHHW allow the wire to operate efficiently under high heat. However, even if the insulation supports high temperatures, the breaker, terminal lugs, and connected devices must also be rated equally. NEC requires the lowest-rated component to determine the final usable ampacity.

NEC Guidelines for 10 Gauge Wire Ampacity

The National Electrical Code provides standardized ampacity charts that electricians must follow when selecting 10 AWG wire. These guidelines consider conductor material, temperature ratings, ambient conditions, and installation specifics such as conduit fill. The NEC rules ensure electrical systems remain safe and prevent overheating, arc faults, and fire hazards. For example, 10 AWG copper is limited to 30A when used for household branch circuits due to 60°C terminal ratings, even if the insulation supports higher ampacity. Always follow NEC Table 310.16 and local building codes for compliant installation practices.

Maximum Safe Amp Load for 10 AWG Wire

The maximum safe amp load for 10 gauge wire depends on the weakest rating among insulation, terminals, and connected devices. In most homes, 10 AWG copper is installed on 30-amp breakers, which ensures long-term reliability without excessive heat. Even though the wire may support higher amps at certain temperature ratings, the breaker protects the system from overloads and wiring damage. Aluminum 10 AWG supports lower loads and therefore requires more caution during installation. Staying within safe limits increases wire lifespan, improves electrical efficiency, and prevents dangerous conditions.

Factors That Influence 10 Gauge Wire Amp Capacity

Several factors affect the ampacity of 10 AWG wire, including conductor material, insulation type, installation method, ambient temperature, and wire bundling. Copper wires naturally carry more amps due to better conductivity, while aluminum requires derating. Wires installed in hot environments, such as attics, must also be derated because heat reduces current-carrying capability. When multiple wires are bundled tightly, airflow decreases and heat accumulates, lowering permissible amp levels. Choosing the correct insulation and installation method ensures that the wire can carry its intended load safely and efficiently.

Why Ampacity Changes With Insulation Type

Different insulation materials have different heat tolerances, which directly impact a wire’s ampacity. For example, THHN insulation can withstand up to 90°C, allowing 10 AWG wire to carry more current than cables with lower-rated insulation such as UF-B or TW. Higher temperature-rated insulation reduces thermal stress and prevents premature insulation wear. Insulation also determines where a wire can be installed—wet locations, underground runs, and high-heat environments all require specific insulation types that affect ampacity. Selecting the right insulation ensures both safety and performance.

Ampacity Differences Between Solid and Stranded 10 AWG

Solid 10 gauge wire consists of a single metal conductor, while stranded wire contains many smaller wires twisted together. Although both types generally share the same ampacity rating, stranded wire may carry current more efficiently in high-flex or vibration-prone environments. Stranded conductors also dissipate heat more evenly, making them ideal for long runs or areas requiring frequent movement. Solid wire is more rigid and mainly used in residential branch circuits. Although the difference in ampacity is minimal, choosing the right type ensures better durability and installation ease.

Voltage Drop Considerations for 10 Gauge Wire

Voltage drop becomes a concern when 10 gauge wire is used over long distances or high-load circuits. As current travels through the wire, resistance causes a loss of voltage, which can lead to dimming lights, appliance malfunction, or overheating. To minimize voltage drop, electricians may increase the wire size or limit the wire length based on load. Typically, a 3% voltage drop is the recommended maximum for branch circuits. Calculating voltage drop ensures that the connected devices receive sufficient power and operate safely and efficiently.

Copper vs Aluminum 10 Gauge Wire

Copper handles more amps than aluminum due to its superior electrical conductivity and lower resistance. This means copper generates less heat under load, making it safer and more efficient for demanding circuits. Aluminum, while lighter and cheaper, requires a larger gauge to match the ampacity of copper. For high-load appliances, HVAC systems, or long wiring runs, copper typically delivers better stability and performance. Aluminum still plays a role in certain applications, but copper remains the preferred choice for residential and commercial wiring where reliability is essential.

When comparing amp ratings, 10 AWG copper wire safely carries 30–40 amps, depending on insulation temperature rating, while 10 AWG aluminum carries 25–35 amps. This difference may seem small, but it becomes significant under continuous loads or high heat environments. Copper maintains voltage better over distance, resulting in reduced voltage drop, whereas aluminum requires compensation with larger wire sizes. Electricians often refer to NEC guidelines to ensure proper selection between these two materials. Choosing the right conductor helps avoid overheating, premature insulation failure, and electrical inefficiencies.

Copper’s atomic structure allows electrons to flow more freely, resulting in lower resistance and heat generation. This efficiency means copper can safely handle higher current levels without risking insulation damage. Additionally, copper’s high melting point enhances its ability to withstand overloads better than aluminum. Another advantage is copper’s durability—connections remain more stable over time because copper is less prone to expansion, oxidation, or loosening. These qualities collectively make copper the superior material for delivering reliable amp capacity in residential, commercial, and industrial circuits.

Copper wiring is significantly more expensive than aluminum due to its global demand, superior conductivity, and longer lifespan. Aluminum is a budget-friendly alternative used in many large-scale electrical installations, especially where long runs are required. Although aluminum costs less upfront, its lower ampacity may require upsizing to a larger gauge, which reduces savings. Maintenance costs can also be higher with aluminum because connections require special anti-oxidation compounds and periodic inspection. Choosing between copper and aluminum depends on load needs, budget, and installation environment.

Aluminum may be preferred in projects where cost efficiency and weight reduction are important, such as long feeder runs or utility applications. It is also commonly used in service entrance wiring and large-scale power distribution systems. Aluminum is lightweight, making installation easier, especially in conduits over long distances. However, electricians must follow strict guidelines to prevent overheating, oxidation, and loose terminals. Aluminum 10 AWG should only be used when amp requirements fall within safe limits and where installation conditions follow NEC recommendations.

Wires rated for 60°C insulation, such as TW or UF cables, have the lowest ampacity for 10 AWG conductors. These wires are typically limited to 30 amps for copper and 25 amps for aluminum. Lower temperature ratings mean the insulation cannot withstand excessive heat, so current flow must be restricted. These insulation types are commonly used in older homes, underground feeders, and basic residential installations. When working with 60°C-rated wire, it’s important to follow NEC terminal temperature limitations to avoid overheating or insulation failure.

Ampacity of 10 Gauge Wire With 75°C Insulation

Wires with 75°C insulation—such as RHW, THWN, or THHW—allow 10 AWG copper to carry 35 amps and aluminum to carry 30 amps. This mid-range temperature rating is suitable for both residential and commercial applications where moderate heat resistance is necessary. The 75°C rating provides better flexibility in installation and offers increased safety margins under load. Many breaker panels and terminal lugs are rated for 75°C, making this insulation category widely used. For most wiring installations, 75°C insulation provides a good balance of ampacity and safety.

Ampacity of 10 Gauge Wire With 90°C Insulation

With 90°C-rated insulation, such as THHN or XHHW, 10 AWG copper wire can handle up to 40 amps, while aluminum can carry 35 amps. This higher temperature rating allows the wire to operate safely under demanding conditions, such as long runs, high heat environments, or heavy continuous loads. However, NEC rules often require derating based on terminals or ambient temperatures, meaning you cannot always use the full 90°C ampacity. Still, the enhanced performance makes 90°C wires a top choice in modern electrical installations requiring maximum reliability and efficiency.

THHN/THWN 10 Gauge Wire Amp Rating

THHN and THWN wires are among the most common types of 10 AWG conductors used in homes and businesses. With a 90°C dry rating (THHN) and 75°C wet rating (THWN), these wires provide excellent ampacity and flexibility. For 10 gauge copper, amp ratings range from 35–40 amps, depending on conditions. These wires are often used in conduit, commercial buildings, and heavy-load circuits. Their durability, high heat resistance, and versatility make them a preferred choice for electricians needing reliable performance in demanding environments.

XHHW Insulation and Its Amp Capacity

XHHW insulation is known for its moisture and abrasion resistance, making it ideal for both indoor and outdoor installations. With a 90°C temperature rating, 10 AWG copper XHHW supports up to 40 amps, offering excellent handling of high heat environments. XHHW is particularly popular in industrial settings, feeder lines, and long-distance wiring due to its mechanical toughness. The enhanced insulation helps reduce the risk of damage during pulling or installation. For projects requiring durability and high ampacity, XHHW is a strong candidate over other insulation types.

UF-B 10 Gauge Underground Cable Ampacity

UF-B (Underground Feeder) cable is designed specifically for direct burial and outdoor use, which makes it more durable and moisture resistant than standard indoor cable. For 10 AWG copper UF-B, the ampacity is typically limited to 30 amps, following the 60°C rating required for this cable type. Although its insulation is rugged, it cannot be rated at higher temperature categories like THHN or XHHW. UF-B is commonly used for outdoor lighting, garden circuits, sheds, and detached buildings. Because it operates at lower amp limits, proper breaker selection is essential to ensure long-term safety.

NM-B (Romex) 10 AWG Amp Rating

NM-B (commonly known as Romex) is one of the most widely used 10 AWG cables in residential wiring. Due to NEC rules, NM-B must use the 60°C ampacity, even though the insulation itself is rated at 90°C. This limits 10 AWG copper NM-B to 30 amps. NM-B is used for large appliances such as water heaters, window AC units, electric dryers (depending on load), and multi-outlet branch circuits. Its ease of installation and affordability make it a favorite among electricians. However, it is not suitable for wet locations or outdoor use.

Outdoor vs Indoor Amp Ratings for 10 Gauge Wire

Outdoor installations often expose wires to higher temperatures, moisture, sunlight, and soil conditions, all of which may reduce ampacity or require specific insulation types. Indoor installations, on the other hand, typically provide stable temperatures and controlled environments, allowing wires to maintain their listed amp ratings more reliably. For example, THHN used indoors can safely handle up to 40 amps, while the same gauge in UF-B outdoors may be limited to 30 amps. Always select wire rated for the environment to avoid overheating and premature insulation failure.

Temperature Ratings and Their Impact on Amps

Temperature ratings determine how much heat the wire insulation can safely endure while carrying electrical current. Higher temperature ratings allow for higher ampacity because the insulation can withstand more heat without breaking down. For example, 90°C wires like THHN offer significantly more current-handling capability than 60°C wires like TW or UF-B. Ambient temperatures also matter—wires installed in hot attics or under heavy loads may require ampacity derating. Understanding temperature limits ensures your circuits remain safe, efficient, and fully code-compliant.

Moisture-Resistant Insulation Types for 10 AWG

Moisture-resistant insulation such as THWN, XHHW, and UF-B is essential for wiring in damp environments, outdoor installations, underground trenches, or areas prone to condensation. These insulation types prevent water penetration, corrosion, and short circuits. They also maintain ampacity more reliably under wet conditions when compared to dry-rated wires. For 10 AWG conductors, moisture-resistant insulation ensures stability, reduces electrical hazards, and maintains consistent performance despite environmental challenges. Choosing the correct insulation type helps protect both the conductor and the connected devices.

Applications of 10 Gauge Wire

10 gauge wire is widely used in homes for circuits requiring moderate to high current levels. Typical applications include electric water heaters, kitchen appliances, small air conditioning units, and large tools in garages or workshops. Because 10 AWG wire handles up to 30 amps in residential installations, it offers enough capacity for many mid-range electrical loads. Homeowners often rely on it for dedicated circuits where reliability and safety are critical. Its versatility and wide availability make it a standard choice for electricians working in residential environments.

Is 10 Gauge Wire Good for Large Appliances?

Yes — 10 gauge wire is commonly used for many large appliances that require up to 30 amps. This includes electric water heaters, dishwashers, built-in ovens, and some air conditioner units. The wire’s ampacity and sturdy construction make it suitable for handling sustained loads without overheating. However, certain appliances like full-size electric ranges or high-demand dryers may require 8 AWG or 6 AWG wire. Always check manufacturer specifications before installation to ensure compatibility and avoid overloading the circuit.

Using 10 AWG Wire for HVAC and AC Units

10 AWG wire is frequently used for HVAC systems, especially for smaller air conditioning units, heat pump auxiliary loads, or furnace circuits. HVAC equipment often requires stable, dedicated circuits due to high starting currents and continuous operation. With its 30A capacity at 60°C, 10 gauge wire provides the ideal balance between safety and performance. When used with THHN or XHHW insulation, the wire may support higher ampacity depending on the terminal ratings. Professional installation ensures the system meets NEC and manufacturer requirements.

Can You Use 10 Gauge Wire for Water Heaters?

Many electric water heaters run safely on 10 gauge wire, particularly units with a 30-amp rating. Smaller single-element heaters and medium-size residential units often match the ampacity of 10 AWG copper. Because water heaters are continuous loads, NEC requires circuits to be sized at 125% of the heater’s amperage, making 10 AWG a common and appropriate choice. However, larger dual-element or high-capacity heaters may require thicker wires. Always verify the wattage and amperage label on the heater before selecting wire size.

Is 10 Gauge Wire Suitable for Electric Dryers?

Most full-size electric dryers require 30–40 amps, which typically calls for 8 AWG or 10/3 cable depending on the model. Some compact or low-wattage dryers, however, can run on 10 gauge wire if their amperage aligns with the wire’s safe amp rating. If the dryer requires more than 30 amps, 10 AWG should not be used under any circumstances. Using an undersized wire can lead to overheating, poor performance, or serious electrical hazards. Always compare the appliance specifications with NEC recommendations.

Using 10 AWG Wire for Electric Ranges

Electric ranges usually require 40–50 amps, which exceeds the capacity of 10 gauge wire. In most cases, 8 AWG or 6 AWG conductors are required. Only smaller plug-in countertop ranges or induction units designed for lower amperage loads may safely use 10 AWG wire. For full-size kitchen ranges, using 10 gauge wire is unsafe and violates electrical code. Checking appliance ratings before wiring prevents overloads and ensures proper performance of cooking equipment.

Outdoor Applications of 10 Gauge Wire

10 AWG wire is ideal for outdoor applications such as powering detached structures, garden lighting circuits, pumps, and small outdoor AC units. When using 10 gauge wire outdoors, insulation type is crucial — UF-B or THWN in conduit is typically required to handle moisture, sunlight, and temperature variations. Ampacity may be lower outdoors due to temperature exposure, so derating must be considered. These installations must follow strict NEC guidelines to maintain safety and durability in harsh weather conditions.

Solar System Applications for 10 AWG Wire

In solar energy systems, 10 AWG wire is commonly used for connecting solar panels, arrays, inverters, and combiner boxes. Because solar installations often involve high temperatures and continuous current flow, wires like USE-2, THHN, or PV-rated cables are preferred. The wire’s ampacity is suitable for many residential solar setups, especially those with moderate output. Proper wire selection reduces voltage drop and ensures efficient power transfer within the PV system. Always follow solar manufacturer specifications and NEC Article 690 for compliance.

Using 10 Gauge Wire for Underground Runs

Underground circuits require wire designed for moisture, soil contact, and physical durability. UF-B cable or THWN in a watertight conduit is commonly used for 10 AWG underground runs. Due to burial depth and environmental heat, ampacity may be derated to ensure safe operation. This wire is often used to power sheds, garages, outdoor kitchens, or security lighting. Long distances may require upsizing the conductor to control voltage drop. Proper burial depth and GFCI protection are required by electrical codes.

Commercial Uses for 10 AWG

In commercial environments, 10 AWG wire is used for circuits powering lighting systems, industrial tools, small machines, air compressors, and HVAC components. It offers a balance between strength and flexibility, allowing reliable operation in demanding electrical systems. Commercial buildings often use THHN or MC cable for 10 AWG due to better mechanical protection and higher ampacity. The wire’s durability makes it a solid choice for long runs through conduit or raceway systems. Ensuring proper amp rating and installation methods keeps the system code-compliant and efficien

Conclusion

Understanding how many amps a 10-gauge wire can handle is essential for designing safe, compliant, and efficient electrical systems. Because ampacity depends on multiple factors—including copper vs. aluminum conductors, insulation temperature ratings, installation conditions, and voltage drop—there is no single universal amp rating for 10 AWG wire. In most household applications, 10-gauge copper wire is rated for 30 amps, while aluminum wire of the same size carries slightly less amperage due to higher electrical resistance. However, specialized insulation types like THHN and XHHW, combined with high-temperature ratings, can allow 10-gauge wire to handle more amps under specific conditions.

Selecting the right wire for the right application not only ensures safe long-term operation but also prevents overheating, equipment failure, and code violations. Whether you’re wiring an AC unit, water heater, electric dryer, or solar installation, matching wire size to breaker capacity and load demand is the foundation of proper electrical design.

Proper planning, adherence to NEC guidelines, and avoiding overloading are the keys to keeping your electrical system reliable and safe. When in doubt, always consult a licensed electrician or refer to NEC tables to ensure every installation meets code and performance expectations.

FAQs

1. How many amps can 10-gauge copper wire handle?

10-gauge copper wire typically handles 30 amps under standard NEC guidelines with 60°C or 75°C insulation ratings. Under certain conditions—such as using THHN wire with a 90°C rating—the ampacity can increase, but breaker size must still match NEC limitations. In most residential setups, 30 amps is the safe and accepted maximum.

2. How many amps can 10-gauge aluminum wire handle?

10-gauge aluminum wire carries fewer amps than copper due to higher resistance and lower conductivity. Generally, 10-gauge aluminum is rated for 25 amps, though it may differ slightly based on insulation type and temperature ratings. It should never be used where 30-amp loads are expected unless specifically allowed by code.

3. Can 10-gauge wire handle 40 amps?

No, standard 10-gauge wire should NOT be used on a 40-amp breaker. A 40-amp circuit typically requires 8 AWG copper or 6 AWG aluminum, depending on installation and insulation type. Connecting 10-gauge wire to a 40-amp breaker poses a serious fire hazard due to overheating.

4. Is 10-gauge wire safe for a 30-amp breaker?

Yes. In almost all residential installations, 10 AWG copper is the correct and safe wire size for a 30-amp breaker. This applies to appliances like water heaters, AC condensers, dryers, and some EV chargers. Always verify insulation type and conductor material.

5. What insulation type gives the highest ampacity for 10 AWG wire?

THHN insulation, which is rated for 90°C, provides the highest ampacity for 10-gauge wire. It can safely carry up to 40 amps according to the 90°C ampacity table, but NEC still limits breaker sizing to the 60°C or 75°C column in many cases.

6. Can I bury 10-gauge wire underground?

Yes, but the wire must be rated for direct burial—such as UF-B cable—or be placed inside conduit using THWN or XHHW wire. Underground runs may require accounting for temperature and moisture exposure, which affect ampacity and voltage drop.

7. Does voltage drop affect ampacity for 10-gauge wire?

Voltage drop doesn’t change the wire’s amp rating but affects performance over long distances. For long runs—typically over 50–100 feet—you may need thicker wire to prevent voltage loss. A voltage drop calculator or NEC guidelines should be used for precise planning.

8. Can I use 10-gauge wire for a 240-volt circuit?

Yes. 10 AWG wire can be used on 240-volt circuits as long as the load does not exceed the wire’s amp rating. Many 240-volt appliances such as dryers, water heaters, and air conditioners commonly use 10-gauge wire on a 30-amp breaker.

9. Is solid or stranded 10 AWG better for amp capacity?

Both solid and stranded 10-gauge wires have roughly the same amp rating. The main difference is flexibility—stranded wire is commonly used in conduit or where vibration occurs, while solid wire is more typical in household Romex installations. Ampacity differences are minimal.

10. What happens if I overload 10-gauge wire?

Overloading 10-gauge wire leads to excessive heat buildup, which can melt insulation, damage appliances, and cause electrical fires. Breakers are designed to prevent overload, so pairing the wire with the correct breaker size is essential for safety.

Keep an eye for more latest news & updates on premiumtechy!